Hole collapse is a common challenge in rock drilling, especially in soft, loose, or fractured geological formations. One of the most critical consequences of this issue is anchor collapse, the failure of the anchoring system due to the instability of the borehole.

This can lead to project delays, safety risks, and additional costs. To ensure the structural integrity of drilling operations, it’s vital to implement practical methods that prevent anchor collapse from the outset.

1. Utilize Self-Drilling Anchor Systems

One of the most reliable ways to prevent anchor collapse is by using self-drilling anchor (SDA) systems. These systems integrate drilling, anchoring, and grouting in one continuous process, which is especially beneficial in unstable ground where borehole walls tend to collapse quickly.

One of the most reliable ways to prevent anchor collapse is by using self-drilling anchor (SDA) systems. These systems integrate drilling, anchoring, and grouting in one continuous process, which is especially beneficial in unstable ground where borehole walls tend to collapse quickly.

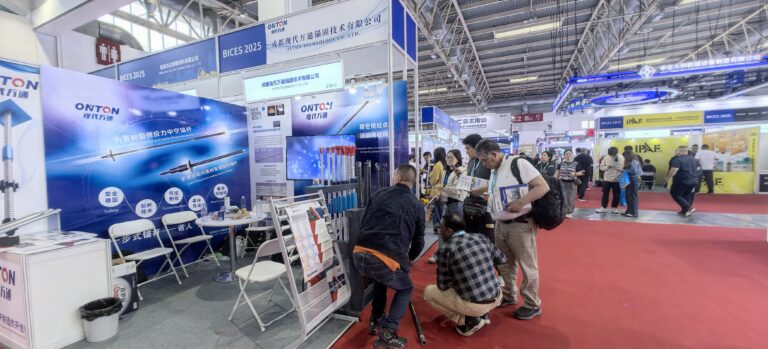

A great example is the Self-Drilling Anchor Bolt – R32N offered by Onton Bolt. This product features a hollow bar that allows grout to be pumped through the bar during drilling.

As a result, the surrounding soil or rock is stabilized immediately, minimizing the risk of collapse. The R32N’s high-strength threads ensure strong load transfer, making it an ideal choice for tunneling, mining, and slope stabilization projects where anchor collapse is a serious concern.

Moreover, SDA systems significantly reduce the need for temporary casings or multiple equipment setups, thus speeding up the installation process and reducing labor costs. They are also well-suited for confined or hard-to-access areas where traditional anchoring methods are difficult to implement.

2. Implement Casing Advancement Techniques

Casing advancement is another effective method, particularly useful in granular or loose formations. This technique involves inserting a steel casing simultaneously with the drill bit to support the borehole walls during drilling.

The casing prevents the walls from falling inward, allowing the anchor to be safely placed without the risk of anchor collapse.

This method is especially beneficial in projects requiring deep anchoring or where groundwater may destabilize the borehole. The temporary or permanent casing maintains borehole diameter and alignment, which is essential for the correct positioning of anchors.

Casing advancement not only improves accuracy but also enhances safety by maintaining structural integrity during critical drilling stages.

3. Employ High-Quality Grouting Practices

Proper grouting is essential for anchor reliability. Incomplete or low-quality grout can result in voids around the anchor, weakening its load-bearing capacity and increasing the risk of anchor collapse over time.

To prevent this, it’s important to use high-quality cementitious grouts with the correct viscosity and flow characteristics for the job.

Ensure the borehole is completely filled to create a strong bond between the anchor and the surrounding formation. This not only locks the anchor in place but also transfers loads evenly, reducing stress points that might lead to anchor collapse.

Additionally, monitoring grout pressure during injection helps identify potential voids or weak zones. Post-grouting testing and inspection should be part of your quality assurance protocol to confirm the structural integrity of the installed anchors.

Conclusion

Preventing borehole and anchor collapse during rock drilling requires the integration of advanced tools and smart techniques. Self-drilling anchor systems like the R32N from Onton Bolt offer immediate stabilization.

Casing advancement supports the borehole during critical stages. High-quality grouting ensures long-term anchor integrity.

Together, these methods provide a reliable framework for safe and efficient rock drilling operations, especially in challenging geological conditions. Taking proactive steps in the early stages of the project can save significant time, cost, and risk in the long run.