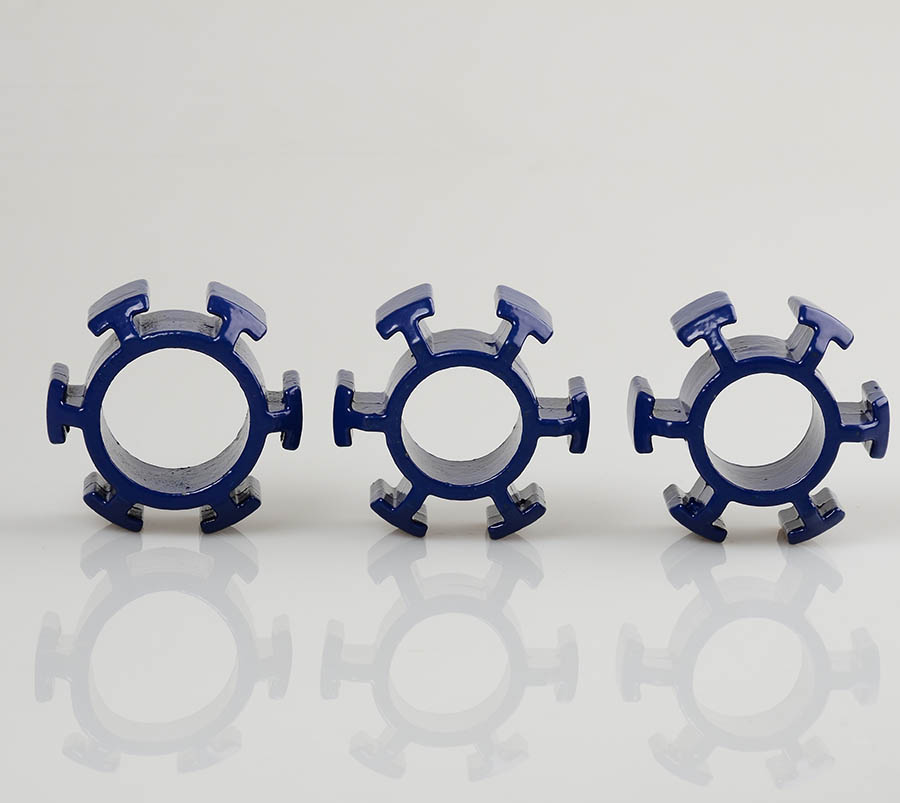

With R thread (ISO 10208 & ISO 1720) and T thread (T international standard), the self drilling threaded anchor bars could be left hand or right hand thread.

R thread and most T thread anchor rods usually left hand, and T73 anchor bar is right hand thread. But the thread direction could be customized according to customers’ requirements.