Understanding the Role of Rock Anchor Bolts in Modern Construction

Rock anchor bolts are essential components in stabilizing geological structures such as tunnels, slopes, and underground mines. By securing unstable rock masses and distributing loads evenly, these bolts ensure structural integrity in both civil and mining projects. As construction techniques evolve and infrastructure projects become increasingly demanding, the performance requirements for rock anchor bolts have risen significantly.

A number of specialized companies are innovating in this field. Among them, ONTON has emerged as a notable name, pushing the boundaries with patented technologies that respond to real-world challenges in tunneling and geotechnical engineering.

Why Choose ONTON

ONTON is not just a manufacturer—it is a strategic engineering partner redefining how rock anchor bolt systems are conceived, manufactured, and implemented. Here’s what makes ONTON the preferred choice for geotechnical professionals worldwide:

-

Deep R&D Commitment with Patented Technology

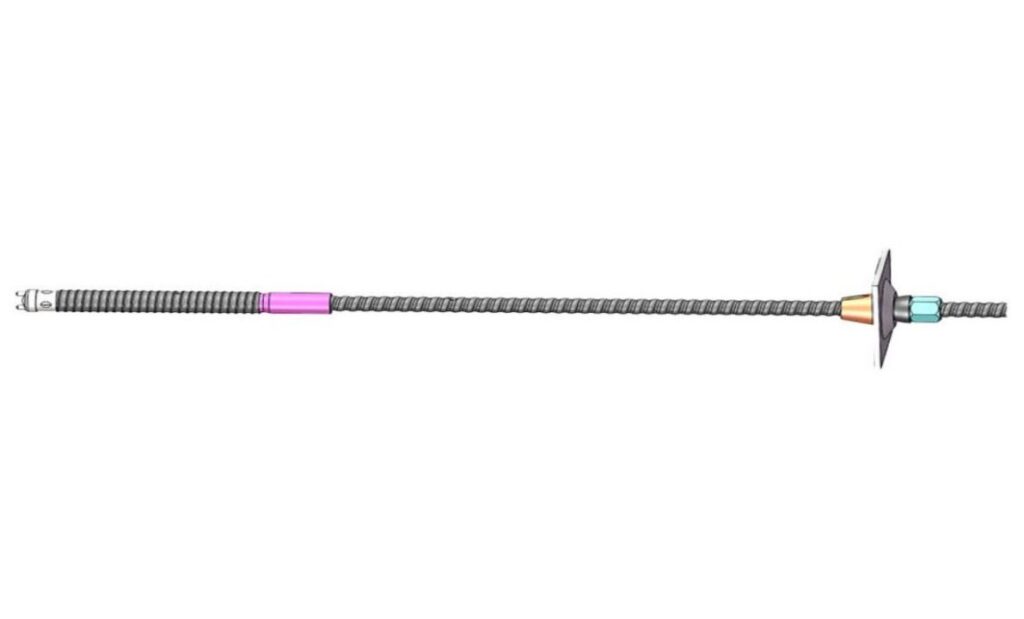

ONTON’s innovation is not theoretical—it is practical, field-tested, and patent-protected. The Build-in-resin Prestressed Self Drilling Hollow Bolt developed in 2023 is a result of iterative product development and simulation-based refinement, specifically targeting efficiency and anchoring strength in tunnel engineering and beyond. -

OEM Customization Services for Project-Specific Needs

Unlike generic bolt suppliers, ONTON provides end-to-end OEM services, enabling clients to tailor dimensions, materials, tip designs (SDA tips), and coatings to the specific requirements of complex geological conditions. -

Expert Guidance and Knowledge Sharing

ONTON goes beyond product delivery. Its technical support includes professional engineering consultation, anchor system design optimization, and field application advice. Through in-depth SDA tip resources and training modules, ONTON empowers clients to execute anchoring operations more accurately and safely. -

Reliable Quality and Certifications

Their operations comply with ISO standards, and each rock anchor bolt undergoes tensile, torque, and anchorage performance testing before delivery to ensure on-site dependability. -

Efficient Global Logistics System

ONTON maintains a robust export pipeline, offering flexible Incoterms (FOB, DDP, EXW) and quick-turnaround delivery. With reinforced packaging and tracking-enabled logistics partners, ONTON ensures products reach international job sites safely and on time.

By integrating customization, engineering depth, and operational reliability, ONTON is not just keeping up with industry expectations—it is setting the new benchmark for high-performance rock anchor bolt solutions.

Key Features to Look for in Rock Anchor Bolts

When evaluating rock anchor bolts, professionals typically consider the following performance criteria:

-

Drilling and installation efficiency

-

Anchorage strength and reliability

-

Corrosion resistance

-

Suitability for complex geological conditions

-

Compatibility with automated equipment

ONTON: A Standout Manufacturer in 2025

As a trailblazer among rock anchor bolt manufacturers, ONTON has brought significant innovation to the market with its Build-in-resin Prestressed Self Drilling Hollow Bolt, patented in late 2023. This new-generation bolt system offers a comprehensive upgrade to traditional self-drilling anchor bolts, making it especially effective for tunnel engineering and other high-risk applications.

ONTON’s Core Innovations Include:

-

Embedded resin capsule with tapered anchor head

Prevents common issues like capsule drop-out or insertion failure in partially collapsed holes, ensuring precise and reliable anchoring. -

Two-step installation process

Streamlined workflow dramatically reduces installation time. A single bolt can be installed in under 4.5 minutes, enhancing project efficiency on large-scale tunneling jobs. -

Thickened rod body with internal blades

Improves mechanical drilling capacity, supports full mechanization of anchor bolt installation, and eliminates negative impact from residual capsule wrappers. -

Optimized anchorage matching system

Enhances bond strength and enables anchorage forces exceeding 100kN, offering improved performance in critical structural zones.

With this product, ONTON doesn’t merely follow industry standards—it redefines them. The rock anchor bolts manufactured by ONTON are quickly becoming a preferred choice for projects demanding both speed and reliability.

Choosing the Right Rock Anchor Bolt Manufacturer: What to Consider

To identify a reliable supplier, decision-makers should evaluate several core dimensions:

R&D capabilities

Does the manufacturer actively improve their rock anchor bolts to address field-specific challenges?

Certifications and compliance

Are the products compliant with international standards, such as ISO or CE?

After-sales support

Is there robust technical guidance and training available for installation and troubleshooting?

Global logistics experience

Can the manufacturer ensure timely deliveries for international projects without delays?

Among the many manufacturers in China, companies like ONTON distinguish themselves by offering a full-spectrum service package: strong R&D to tackle industry-specific demands, internationally recognized certifications like ISO and CE for quality assurance, dedicated after-sales technical support to ensure smooth implementation, and proven global logistics capabilities for timely delivery. These strengths demonstrate ONTON’s commitment to providing not just quality products, but also comprehensive solutions tailored to customer needs.

Expanding Applications of Rock Anchor Bolts in 2025

While tunneling remains the primary domain for rock anchor bolts, the range of application is expanding rapidly. Particularly in 2025, demand is growing in:

-

Open-pit mining

Where stability of excavation walls is vital for operational safety. -

Urban slope stabilization

Especially in hilly cities investing in infrastructure resilience after extreme weather events. -

Hydropower dam reinforcement

Where anchors must perform in wet, high-pressure environments.

As these sectors grow, the need for durable, easy-to-install, and performance-assured rock anchor bolts becomes more urgent—further amplifying the role of innovative manufacturers like ONTON.

Final Thoughts: Rock Anchor Bolts and the Industrial Edge

In a time where safety and efficiency are paramount in infrastructure development, choosing high-performance rock anchor bolts is not just an engineering decision—it’s a strategic one. Manufacturers are offering the world more than just affordable solutions; they are delivering value through continuous innovation and on-the-ground engineering insight.

Among them, ONTON stands as a prime example. With its Build-in-resin Prestressed Self Drilling Hollow Bolt, it showcases how deep industry knowledge, R&D commitment, and field-tested results can converge into one high-performance product.

For engineers, procurement teams, and project leaders searching for reliable rock anchor bolts in 2025, turning to top manufacturers—especially ONTON—offers not just peace of mind but a competitive edge.