In geotechnical engineering, tunnelling, mining, and building operations, the service life of self-drilling anchors is crucial. For anchoring soil, rock, and other difficult terrains, these multipurpose systems are the way to go because they integrate drilling and anchoring into one operation.

But how long these systems last is a major factor in how well they work and how much money they save. Self-drilling anchor bar systems develop all the structural systems and reduce other costs, including repair and replacement. This article examines the factors that influence the longevity of these systems, as well as strategies to maximize their lifespan.

What is Service Life?

The service life of a self-drilling anchor screw bar is the amount of time it can efficiently carry out its intended duty before needing to be replaced. When it comes to technology, factors like operating pressures, environmental factors, and material qualities all have a role in determining the service life of a system. Because these parts are subject to harsh environments and heavy loads, self-drilling anchor screw bars systems must have a long service life.

Service Life of the Self-Drilling Anchor System

An Important Consideration for a Long Service Life: The benefits of a longer service life include reduced maintenance needs, lower expenses, and fewer interruptions to current tasks. Engineers may optimise design and installation procedures to create safer and more durable structures by understanding the aspects that affect the service life.

A Life in Design: In the early stages of a project’s design, the expected lifespan of a self-drilling anchor system is established. Both the project’s unique needs and the structure’s anticipated lifespan are considered. An important component in determining the design life is the intended function, load-bearing capacity, and environmental conditions.

Corrosion Mitigation: The breakdown of self-drilling anchor systems due to corrosion is a principal problem that can substantially affect their longevity. Damage to the system’s structural integrity can occur as a result of corrosion caused by exposure to chemicals, moisture, and extreme climatic conditions. Stainless steel self-drilling anchor systems are only one example of how corrosion-resistant materials and protective coatings can prolong service life.

Grouting materials: Grouting is the key to the anchor bolt bonding to the formation, and also provides a layer of protection. Using high-quality cement grout and grouting density can provide a certain alkaline protective environment to inhibit steel corrosion.

Environmental factors: In addition to the product itself, the reason for extending the service life of self-drilling anchors also depends on the surrounding environment. For example, salt spray and saline-alkali soil in coastal areas are extremely corrosive to the environment.

Conclusion

Many factors affect how long self-drilling anchor screw bars last, such as the quality of the material, the method of installation, the surrounding environment, the grouting substance, and the protective layer. Maximising the anchor system’s service life is attainable with an understanding of these elements and the implementation of suitable procedures, guaranteeing long-term durability and dependability in ground support applications. To achieve maximum performance and safety, it is vital to conduct periodic tests, perform maintenance, and follow best practices.

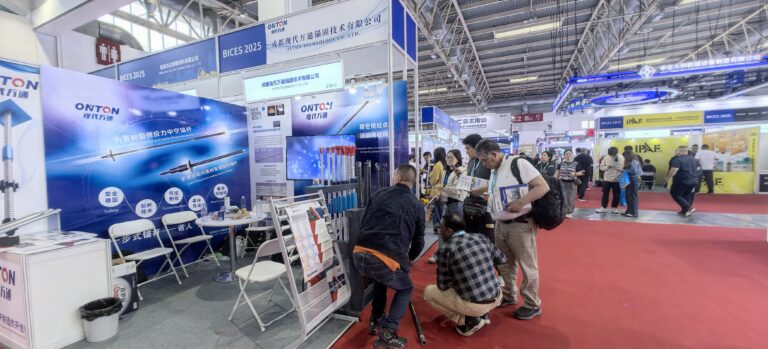

The team of professionals at OntonBolt has a broad background in offering full geotechnical engineering services, and they are experts in making self-drilling anchor screw bars. Get in touch with us at any time for professional advice and first-rate geotechnical anchoring solutions related to self-drilling anchor systems.