The self drilling anchor bar represents a highly efficient ground support system commonly applied in tunneling, slope stabilization, deep foundation works, and mining operations. This anchoring technology streamlines installation by integrating drilling and grouting in a single operation, making it especially effective in weak strata, fractured rock masses, and mixed geological conditions. Its hollow core enables simultaneous grout injection, while the continuous external threading ensures enhanced adhesion and reliable load transfer over the long term.

For projects requiring specific parameters, ONTON also delivers customized anchor bar solutions that can be adjusted in terms of length, diameter, or surface protection. Whether used for pre-support in tunnels, landslide mitigation, or underpinning of existing structures, the system can be engineered to meet diverse project requirements.

I. Key Benefits of Self Drilling Anchor Bar

The self drilling anchor bar offers several notable advantages that make it a preferred reinforcement method in modern infrastructure and mining:

- Combined drilling and grouting: Reduces the number of installation steps, improving efficiency in difficult ground conditions.

- Full-length threading: Allows easy cutting, coupling, and extension, enhancing adaptability at the job site.

- High-grade steel construction:Designed to sustain significant axial and radial forces in deep or unstable terrain.

- Superior corrosion resistance: Available with optional galvanizing or epoxy treatment to ensure long service life in aggressive environments.

These attributes help contractors minimize construction delays, lower operating expenses, and improve overall structural stability.

II. Installation Process of Self Drilling Anchor Bar

The installation of a self drilling anchor bar is designed as a one-step procedure that eliminates the need for pre-drilled casing:

- A drill bit is affixed to the hollow threaded bar.

- The bar is drilled directly into the target ground using rotary-percussive machinery.

- Grout is pumped through the hollow section during drilling to fill surrounding voids.

- Once cured, the grout forms a strong bond with the bar and surrounding ground.

This technique significantly accelerates reinforcement operations in soils prone to collapse or water ingress.

III. Applications Across Engineering Fields

The self drilling anchor bar finds extensive use in a variety of projects:

- Tunneling Support:Provides face and radial reinforcement in subway, highway, and railway tunnels.

- Slope and Embankment Stabilization: Controls erosion and prevents landslides on road cuts and steep slopes.

- Foundation Reinforcement: Strengthens retaining structures, deep excavations, and foundation pits.

Many of these applications benefit from customized anchor bar configurations, allowing adaptation to site-specific geological and structural challenges.

IV. Customized Anchor Bar Options

ONTON offers a wide range of customized anchor bar solutions for projects that require non-standard specifications. Custom features may include:

- Tailored threading for specific coupling or extension requirements.

- Varied lengths and diameters to match unique project scales.

- Enhanced designs for increased load-bearing capacity in mining and tunneling environments.

By providing customized systems, ONTON helps optimize installation, reduce long-term maintenance, and ensure reliable structural performance.

V. Best Practices for Installation and Maintenance

Ensuring the longevity and performance of a self drilling anchor bar system requires proper handling and periodic assessment. Recommended practices include:

- Using approved drilling rigs and compatible grout mixtures.

- Maintaining correct grout proportions to achieve maximum bonding strength.

- Conducting periodic load tests and visual inspections in high-stress areas.

- Selecting customized anchor bar designs with advanced protective coatings in corrosive or water-rich settings.

Following these measures can significantly reduce long-term risks and improve the overall stability of construction and mining projects.

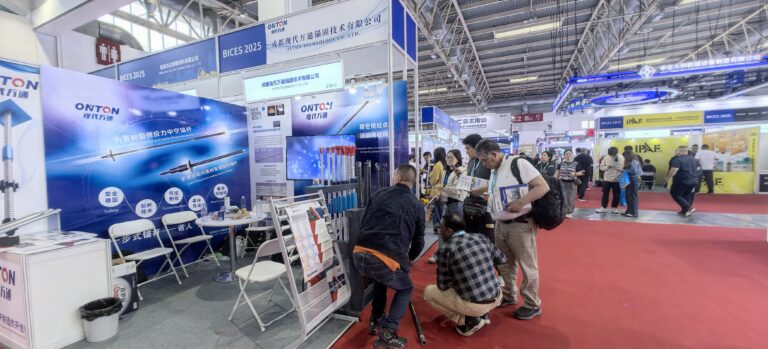

VI. Why ONTON is a Trusted Choice

ONTON Technology Co. Ltd. stands out for its consistent product quality and technical innovation. The company’s self drilling anchor bar systems meet international engineering standards and are backed by strong supply chain support. Our main advantages include:

- In-house production with precision machining

- Fast response for customized anchor bar orders

- Thorough quality inspection procedures

- Reliable after-sales service and documentation

As a global provider, ONTON not only supplies customized anchor bar solutions but also offers consulting on anchoring system selection, delivery logistics, and application support.