Customized IBO Self Drilling Anchors and Special Size Drill Rods

At Onton Bolt, we offer advanced ground support solutions designed for demanding construction and geotechnical environments. Our customized IBO drill rods and IBO self drilling anchor systems combine strength, efficiency, and adaptability, making them the preferred solution for tunnel reinforcement, slope stabilization, and foundation support. By integrating drilling and grouting into a single step, the IBO system ensures stability even in fractured rock, soft soil, or mixed strata.

Whether your project involves urban tunneling, slope protection, or deep foundations, Onton Bolt can provide customized solutions. For personalized guidance, you can always contact us to discuss your project requirements.

Advantages of Customized IBO Drill Rods

Our special size IBO drill rods are engineered to meet diverse geotechnical needs, offering significant advantages over standard rods:

- High drilling efficiency:The self-drilling system performs drilling and grouting simultaneously, saving time and reducing the risk of hole collapse in unstable ground.

- Exceptional durability:Constructed from high-strength alloy steel, these rods resist heavy loads and maintain structural integrity over long-term use.

- Flexible customization:Rods can be manufactured in non-standard sizes, lengths, and diameters, suitable for complex geological conditions or unique project demands.

- Enhanced corrosion resistance:Special surface coatings protect against chemical and environmental damage, extending service life even in aggressive conditions.

- Easy integration:Fully compatible with standard drilling rigs, pumps, and accessories, allowing seamless deployment on existing projects.

These features make customized IBO drill rods ideal for critical infrastructure projects, where precision, reliability, and safety are essential.

How IBO Self Drilling Anchors Work

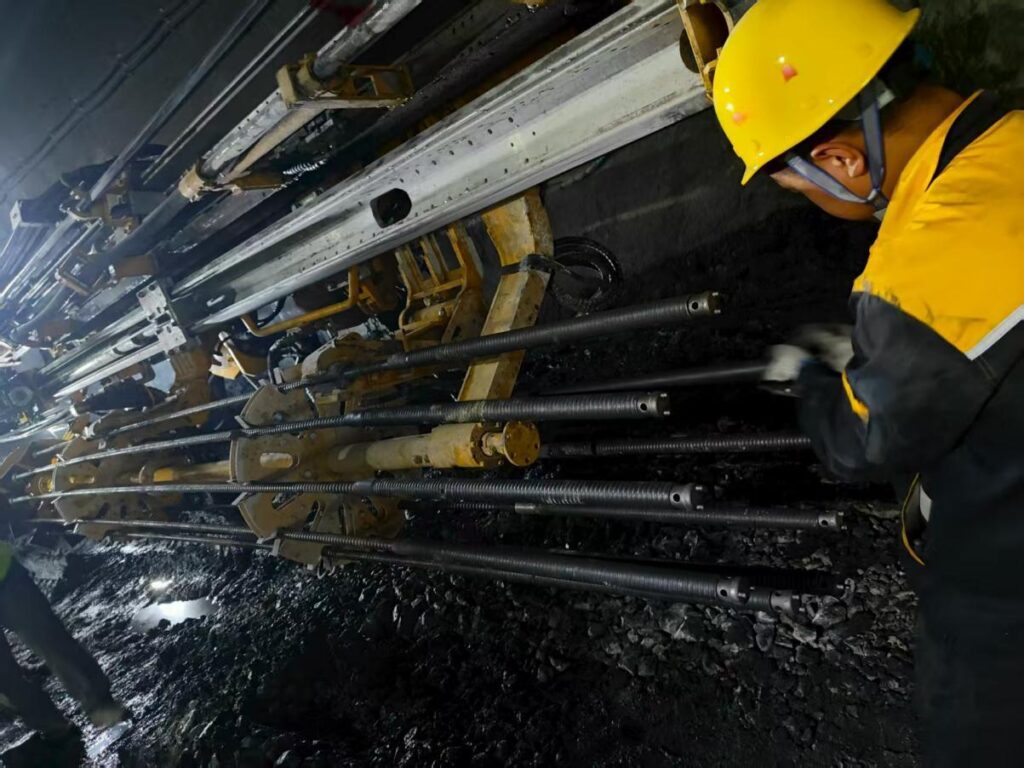

The IBO system uniquely integrates multiple functions—drill bit, drill rod, and grouting pipe—into a single unit. The operation process includes:

- Drilling phase:The hollow rod, fitted with a sacrificial drill bit, efficiently cuts through soil or rock layers, even in mixed or fractured ground.

- Grouting phase:Cement grout is pumped through the hollow rod, filling voids and reinforcing surrounding ground for enhanced stability.

- Anchoring phase:Hardened grout bonds the anchor to the surrounding strata, creating a permanent, reliable support system.

- Finishing:Plates and nuts are installed to transfer load effectively from the ground to the rod system.

This integrated process eliminates the need for casing, particularly beneficial in loose soil, sand, or gravel, reducing project complexity and cost.

Key Benefits of IBO Self Drilling Anchors

- Time efficiency: Drilling and grouting in a single step significantly shortens construction schedules.

- Improved safety: Provides reliable stability in fractured rock or unstable soil, reducing risks of landslides or collapse.

- Versatility: Suitable for micropiles, slope stabilization, retaining walls, tunnels, and foundation reinforcement.

- Reduced equipment requirements: No casing required, minimizing machinery and labor costs.

- Long-term durability: Corrosion-protected rods ensure reliability for permanent installations.

Application Scenarios

IBO anchors and self drilling systems are widely used in:

- Tunnel excavation:Provides pre-support for tunnel crowns, protecting workers and structures during excavation.

- Slope stabilization:Prevents landslides and soil erosion in mountain slopes, riverbanks, and highway cuttings.

- Foundation reinforcement:Stabilizes weak soils under buildings, bridges, retaining walls, and high-rise structures.

- Mining operations:Supports underground chambers, reduces collapse risk, and increases operational safety.

- Hydropower projects:Reinforces dam structures, spillways, and waterway embankments to resist water pressure and erosion.

For projects with challenging ground conditions, our team offers customized IBO solutions. You can contact us for a detailed consultation or request specifications for your site.

Purpose and Scope of Customized IBO Drill Rods

While standard rods can address general construction needs, complex geological conditions often require tailored solutions. For example:

- Tunnels through mixed strata:Require rods of specific lengths and diameters to ensure complete anchoring.

- Slopes with alternating soil and rock layers:Need precise drilling to stabilize each section effectively.

- Foundations with deep or long anchors:Benefit from rods customized for depth and tensile strength.

Customized IBO drill rods reduce the risk of hole collapse, improve grout bonding, and provide long-lasting stability. Onton Bolt supplies both standard and custom solutions, helping contractors reduce downtime, improve efficiency, and enhance safety.

Conclusion

Our customized special-size IBO drill rods offer the perfect combination of strength, flexibility, and efficiency, providing an ideal solution for various complex geological conditions. Onton Bolt ensures reliable performance even under the most challenging site conditions. With customized specifications, your project benefits from precision engineering, long-term stability, and cost-effective construction.

For expert guidance and tailored solutions, contact us today—our team at Onton Bolt is ready to help you achieve safer and more efficient project outcomes.