As cities grow and infrastructure demands escalate, staying updated on industry trends is essential for any anchor bolt manufacturer. From smart integration to advanced materials and global market shifts, here’s a comprehensive look at how OntonBolt aligns with the future of anchoring solutions.

Industry Trends Shaping Anchor Bolt Innovation

The future of anchor systems is determined by a few trends:

- Smart Manufacturing & IoT:

Sensors are now built into machines. They track heat, pressure, and vibration in real time. This makes production faster and reduces downtime. - Stronger and Safer Materials:

Manufacturers are using high-strength alloys and better coatings. These protect bolts from rust and damage. They are especially useful in humid or earthquake-prone areas. - Rising Global Demand:

The anchor bolt market is growing quickly. By 2031, it is expected to be worth billions. Demand is rising in construction, mining, hydropower, and city infrastructure. - Green Production & Online Growth:

Companies now focus on eco-friendly methods. At the same time, e-commerce is becoming a major way to sell fasteners worldwide.

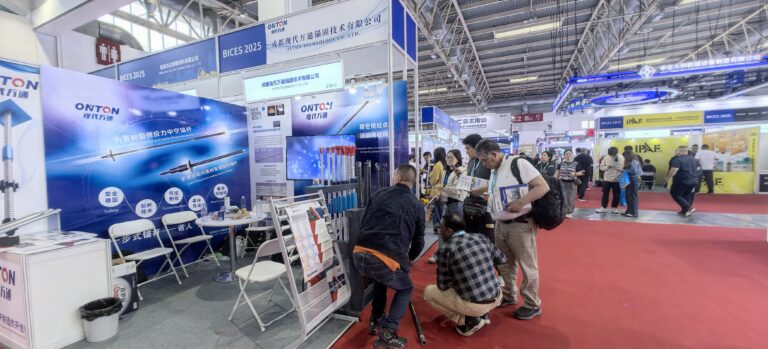

About OntonBolt — Your Trusted Anchor Bolt Manufacturer

As a leading anchor bolt manufacturer, OntonBolt delivers high-performance self-drilling hollow bolts that excel in both stability and reliability. Their top offerings include the:

- R-thread Self-Drilling Hollow Bar – Ideal for loose strata with quick installation via left-hand rope threads. Available in R25–R51 grades.

- T-thread Self-Drilling Hollow Bar – Built for deep tunnels and service loads, compliant with T30–T103 standards.

- Built-in Resin Prestressed Hollow Bolt – 2023 innovation that combines resin grout with prestressing to create better anchoring.

Each product integrates durable materials and precision engineering—perfect for applications like slope stabilization, tunnel support, and foundation reinforcement.

Applications Across Industry Sectors

OntonBolt’s anchor systems are in demand across a wide range of projects:

- Open-pit mining – securing excavation walls for safety.

- Urban slope stabilization – preventing landslides in built-up, hilly areas.

- Hydropower dams – anchoring structures to withstand wet, high-pressure environments.

These use cases highlight how an anchor bolt manufacturer must deliver solutions that balance durability, installation efficiency, and adaptability.

What Makes OntonBolt Stand Out

OntonBolt sets itself apart as an anchor bolt manufacturer through:

- In-house innovation, especially its integrated resin and prestress bolt design.

- Robust materials designed to resist corrosion and wear.

- Tailored solutions, custom to project requirements and site requirements.

- R&D-driven design, ensuring both national compliance and field-tested reliability.

Choosing the Right Anchor System: A Quick Guide

If you’re evaluating anchor solutions, consider the following:

- Geological Conditions: Loose soils benefit from R-thread bars; deep rocky foundations need T-thread systems.

- Load & Safety: For tunnels or heavy-duty use, the resin-prestressed option delivers both bonding and stress control.

- Installation Efficiency: Look for tools that reduce piece count and simplify drilling and grouting.

- Sustainability Needs: OntonBolt aligns with green-building trends as seen across the broader anchor market.

FAQ

Q: What makes OntonBolt a trusted anchor bolt manufacturer?

They fuse durable materials with expert design and hands-on customization, backed by strong R&D.

Q: Are these bolts suitable for seismic or damp environments?

Yes, resin anchoring and corrosion-resistant alloys help anchor bolts perform well even in tough environments.

Q: Can OntonBolt handle non-standard sizes or special projects?

Absolutely, they focus on making custom anchor bolts for specific project needs.

Conclusion

For engineers and project leads, partnering with an agile, innovative anchor bolt manufacturer like OntonBolt means long-term performance and adaptability. As industry trends evolve—tech integration, sustainability, infrastructure growth- OntonBolt stands ready to meet the future of anchoring solutions with precision and reliability.