If you’ve ever been involved in anchoring, tunneling, or stabilizing soil, you already know one simple truth: materials can make or break a job. Pick the wrong ones, and even the best design can turn into a nightmare. One piece of equipment that’s quietly become important on worksites is the self-drilling hollow bar. It’s simply a tool that lets you drill, grout, and anchor without swapping parts or repeating steps.

That’s the upside. The downside? With so many types, lengths, and load ratings out there, deciding which one to use can feel like trying to read a foreign language. In this guide, we’ll strip away the jargon and walk through what these bars actually do. We’ll talk about what details matter most, and how to choose a setup that won’t let you down.

Self-Drilling Hollow Bars, Explained in Plain Terms

Think of a self-drilling hollow bar as a strong steel tube with a drill bit attached to its nose. Instead of drilling a hole, pulling the tool out, and then inserting reinforcement before grouting — the traditional, time-eating process — the bar does everything in one shot. You drill directly into the ground, inject grout through the hollow center, and lock the anchor in place without extra steps.

A typical system comes with a few basic parts:

- The bar itself – a hollow steel tube that takes the load.

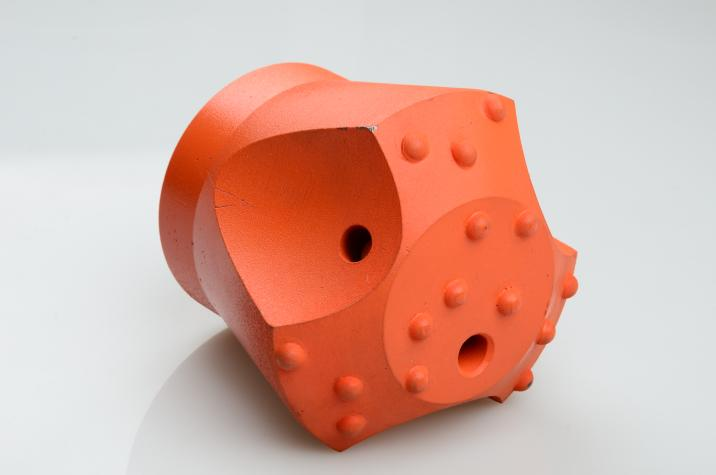

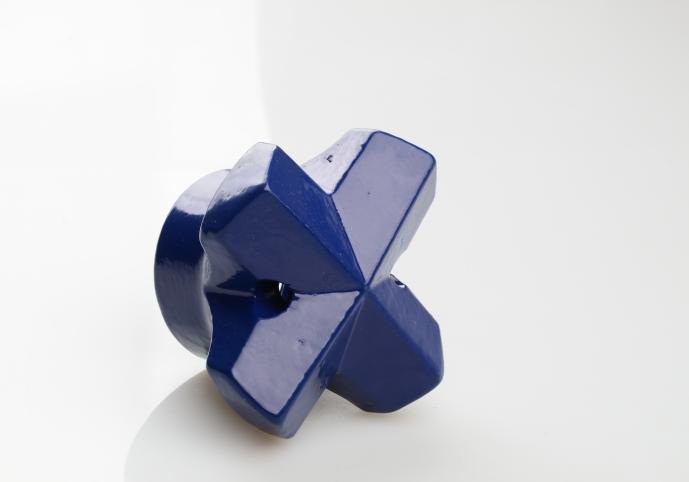

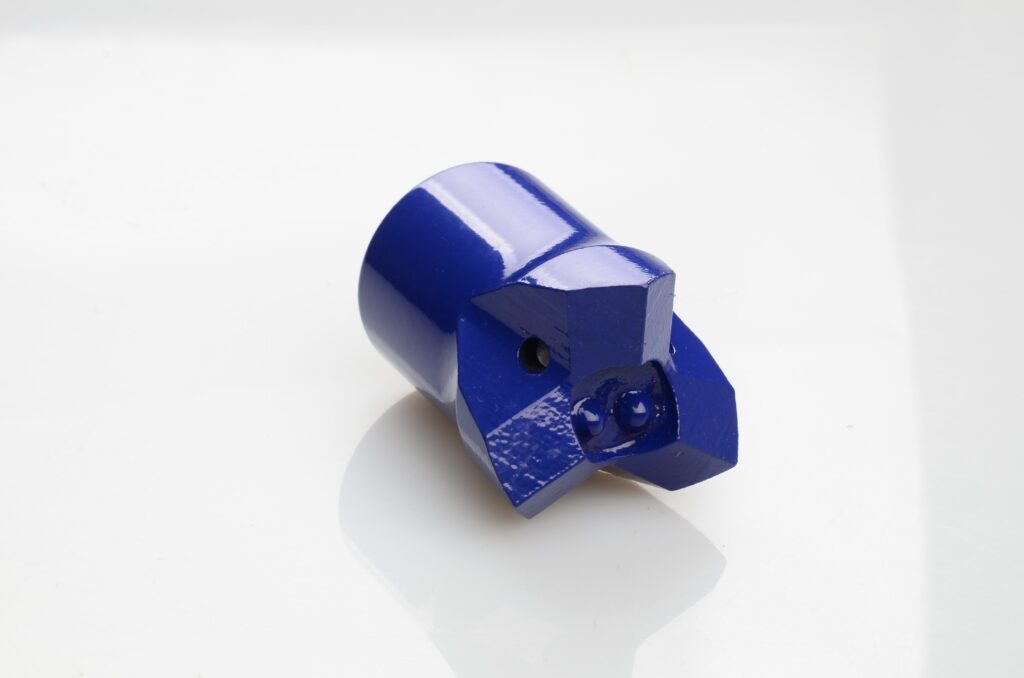

- A drill bit – fitted to the tip to cut through soil or rock.

- Couplers – so you can extend the length if needed.

- Nuts or plates – to secure everything once it’s installed.

These systems show up everywhere — from retaining walls and slope stabilization projects to tunnel construction and foundation support. They’re especially handy in tricky soil conditions where old-school drilling and grouting can be slow or unreliable.

What to Look For Before Buying

Choosing the right bar isn’t only about picking the first one in a catalog. A few ‘small’ details can make a huge difference once you’re on site.

- Ground conditions

Start by understanding what you’re drilling into. Loose soil or soft rock usually calls for a lighter bit and a thinner bar. Dense rock? Go for a heavier-duty setup with a robust drill head that can push through resistance. A quick soil test before you order anything can save you a lot of time — and money.

- Load requirements

Diameter isn’t only about size, but it’s also about strength. Bigger self-drilling hollow bars support more weight, so if you’re dealing with heavy loads or deep foundations, it’s worth going up a size. Many engineers often design with a safety margin in mind, so choosing a bar that exceeds your maximum expected load is good practice. - Corrosion resistance

Corrosion becomes a real concern if the site is near the coast, underground water, or a chemical-rich environment. Galvanized steel or self-drilling hollow bars with protective coatings are a smart investment because they last longer and stay structurally sound over time. - Grout compatibility

The grout is what bonds everything to the surrounding ground. Make sure it’s compatible with the bar material and suited to the project conditions. A poor match can weaken the anchor and shorten its lifespan. - Regulations and standards

Finally, always double-check local construction codes. Some regions require specific certifications or tests before materials are cleared for use. Staying compliant keeps your project legal — and safe.

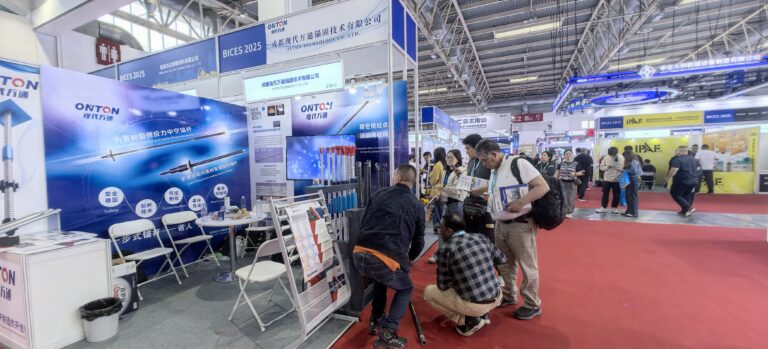

Why Many Projects Use ONTON’s Bars

At ONTON Technology Co., Ltd, we’ve seen how different every project can be. That’s why we produce a variety of self-drilling hollow bars. These include compact, lightweight models for smaller stabilization jobs to high-strength bars designed for deep, demanding work.

Each bar is made from quality steel and thoroughly tested for durability. If your site needs something special — maybe a certain length, a specific coating, or a custom thread — we can create a solution to match. And if you’re unsure where to start, our technical team is always ready to talk through the details and help you choose what’s best.

Contact us today!