In modern mining, tunneling, and construction building projects, self-drilling rock bolts play a crucial role in supporting rock masses and for safety. Homeowners, engineers, and construction professionals are all interested in how these differ from standard anchor bolts.

Having knowledge of their applications, design elements, and performance characteristics is critical to make an intelligent choice of the proper support system. This article will explain the differences between them clearly and professionally and provide important information such as installation efficiency, load-carrying capacity, and environmental conditions.

What are Self Drilling Rock Bolts?

- Definition and Basic Structure

Self drilling rock bolts are mechanical anchors that combine the step of anchoring and drilling into a single operation. As compared to traditional anchor bolts, where pre-drilled holes and resin or grout injection is required, self drilling bolts have a hollow core and threaded tip to provide space for the drill rod penetration into rock directly. Self drilling bolts typically come in 20–32 mm diameter and 1.5 m to 6 m in length, depending upon the geology conditions.

Key Benefits:

- Time Savings – Self drilling bolts save up to 50% of installation time compared to traditional anchor bolts.

- Safety – Constant drilling and grouting eliminate loose rock dangers in installation.

- Flexibility – Applicable to soft to moderately hard rock, underground tunnels, slopes, and mining applications.

Understanding Anchor Bolts

(1)Definition and Composition

Anchor bolts are standard rock support items that require pre-drilled holes and additional grouting or resin to secure them. They typically consist of a steel rod with threaded end and an expansion sleeve. Standard sizes consist of diameters between 16–25 mm and lengths between 1.2 m and 5 m.

(2)Installation Process

- Drill a hole with the specified diameter.

- Screw the anchor bolt in.

- Fill the hole with grout or chemical resin.

- Torque the bolt to the target load-bearing capacity.

Anchor bolts are very dependable in hard rock conditions, with pre-drilling offering accurate placement and bonding.

Principal Differences Between Anchor Bolts and Self Drilling Rock Bolts

(1)Installation Process

Self drilling rock bolts allow one-step drilling and bolting, reducing labor and equipment requirements. Anchor bolts require separate drilling and grouting, potentially increasing installation time and complexity.

- Load-Bearing Capacity

- While both provide firm reinforcement, load-carrying relies on design and material:

- A 22 mm diameter self drilling bolt typically has a load capacity of 150–200 kN axial load.

- An equivalent anchor bolt can handle 200–250 kN, especially in hard, tight rock.

- Ideal Environments

Self drilling bolts are best suited for soft or broken rock due to the immediate anchoring effect. Anchor bolts are utilized in very hard, unbroken rock where high load-carrying and precise location are critical.

(2)Cost Factors

Self drilling bolts are time and equipment savers but may be costlier per unit. Anchor bolts are cheaper per unit but require greater installation effort. Both material and operational costs need to be weighed in cost-benefit analysis.

Practical Applications

Self drilling rock bolts are widely used in metal ore tunnels as well as coal mines for rapid stabilization of newly mined ground.

- Highway and Railway Excavations

Anchor bolts are normally holding retaining walls and rock slopes in hard cuts of limestone or granite.

- Construction of Underground Facilities

Self drilling and anchor bolts may be both included in concrete-lined tunnels, with self drilling bolts servicing faster initial stability and anchor bolts servicing long-term support.

Conclusion

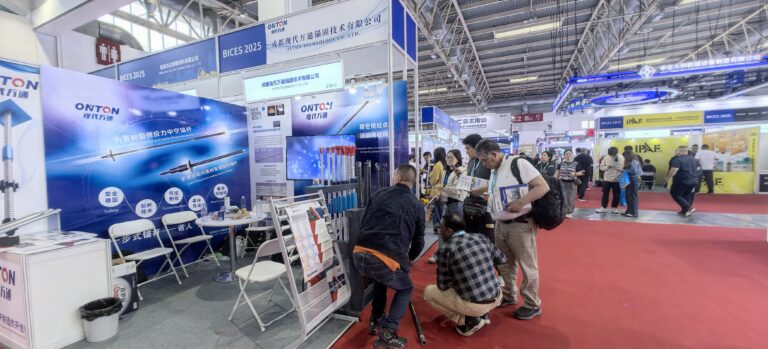

The choice between self drilling rock bolts and anchor bolts depends on geological conditions, project scale, and installation priorities. Self drilling bolts are ideal for rapid installation in soft to moderately hard rock, while anchor bolts suit hard, solid rock needing high load-bearing capacity. By understanding their differences and applications, engineers can select the best option for tunnels, mines, and similar projects, with trusted suppliers like ONTON providing reliable bolts and support.