In civil and geotechnical engineering, reliable anchoring systems provide safety and durability. Among the technologies that are presently widely used for their unmatched advantages is the self-drilling anchor bolt. Alternatively referred to as drill in anchor bolts, self-drilling anchor bolts are top-notch anchoring systems that provide a cost-effective and effective anchor solution in rocks and soils with intricate compositions. Here are five important benefits of using self-drilling anchor bolts in your projects.

Does Away with the Need for Casing

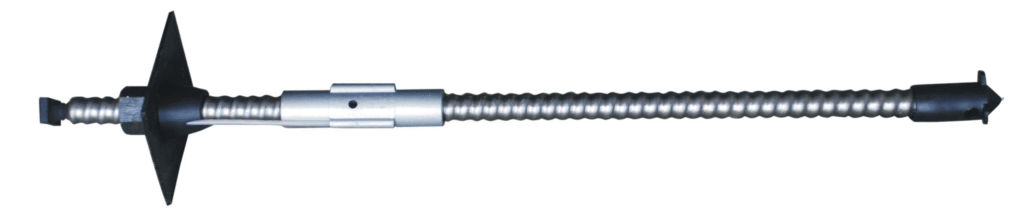

One of the most significant benefits of drill-in anchor bolts is that they do away with the need for pre-drilling and casing in loose or collapsing ground conditions. Engineers would normally have problems with borehole stability in traditional anchoring systems. However, self-drilling anchor bolts like those offered by Ontonbolt combine drilling, grouting, and anchoring into a single effective process. Not only do they cut down on equipment needs, but also on precious time and the cost of labor on the job site.

Speedier Installation Process

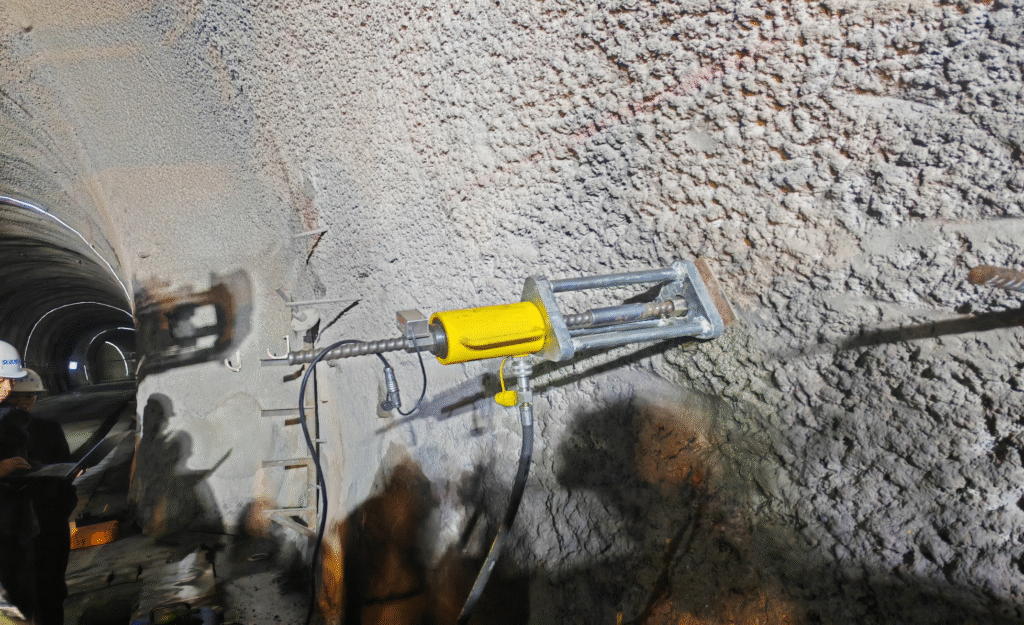

Time-saving is important in construction and infrastructure projects. Self-drilling anchor bolt installation is significantly quicker compared to conventional bolts. Self-drilling anchor bolts allow simultaneous drilling and grouting, and this cuts down the project duration, especially in slope stabilization, foundation, and tunnel reinforcement projects. The lower number of processes makes drilling in anchor bolts a contractor’s favorite option for tight schedules without compromising on quality and safety.

Improved Performance in Challenging Ground Conditions

In those uses where ground conditions are doubtful, such as cracked rock, sand, or weak ground, drill-in anchor bolts are better than standard anchoring systems. Hollow bar construction makes them particularly suited to being pressure-injected with grout, filling spaces and becoming tightly bonded with the surrounding material. The load-carrying capacity is increased, and general stability is achieved. Self-drilling makes drilling through hard ground or mixed ground possible without prior treatment, especially with drill anchor bolts.

Versatility Across Applications

Engineers and contractors enjoy self-drilling anchor bolts due to their adaptability. They are used for a range of applications, including mines, tunnels, retaining walls, and slope stability. Ontonbolt’s product category includes different dimensions and designs of hollow anchor bolts for different geo-conditions. Their anchor bolt drilling is designed to cater to the distinct requirements of both temporary and permanent support systems.

Reduced Overall Cost of Project

Whereas the initial capital investment in drilling anchor bolts may be slightly higher than for conventional systems, overall cost savings are considerable. Reduced utilization of special equipment, fewer steps to installation, smaller project schedules, and lower labor costs make self-drilling anchors a smart cost-saving choice. In addition, improved performance and longer life for these bolts decrease the failure rate and repair cost.

In short, self-drilling anchor bolts—especially those manufactured by well-established companies like Ontonbolt—are a modern, effective, and reliable anchoring solution. From cost-effectiveness to improved performance in challenging terrains, the advantages of using a drill in anchor bolts make them an indispensable tool in today’s geotechnical engineering toolkit. Whether you are building a high-risk tunneling project or stabilizing a steep slope, self-drilling anchors offer both the strength and speed your project needs.