Consumers in today’s global supply chain expect more than reliable products. They want the confidence that every fastener is produced with consistent quality and full accountability.

In order to match this expectation, China bolt manufacturers, led by Onton, have stepped up and placed an extreme priority on quality and accountability, ensuring that their customers can trust their products.

Quality Built Into Every Step

Getting approved raw materials with a constant composition is the first step for suppliers. Steel, alloys, and coatings undergo extensive testing to determine their strength, resistance to corrosion, and suitability for specific uses.

The manufacturing process has likewise evolved. Many factories now use:

- Precision CNC machining, which ensures accurate threading and specifications.

- Automated heat treatment to improve strength and durability.

- AI-driven inspections to identify small defects not visible to the human eye.

Whether in massive machinery or critical infrastructure, these procedures help guarantee that every fastener performs reliably even in the most challenging situations.

Building Trust Through Accountability

Today’s business-to-business environment requires accountability. To ensure that each fastener can be traced back to its source, China bolt manufacturers are now applying barcoding systems, digital records, and batch coding.

In addition to aiding in fast detection of possible problems, this process gives consumers in areas like mining, energy, and construction confidence that the bolts they use comply to strict safety and compliance standards.

Why China Bolt Manufacturers Are Driving Change

China’s bolt industry has advantages that make it a leader in this transition:

- Complete supply chain: the ecosystem enables quick prototyping and cost effectiveness from steelmaking to finishing.

- Smart production: precise machining, automation, and AI-driven inspection are increasingly widely used by manufacturers.

- Rising demand: Industries like infrastructure, renewable energy, and EVs need advanced fastening solutions.

- Global standards: Businesses are being pushed to improve their quality and innovation levels by obtaining international certifications.

Together, these strengths allow Chinese suppliers to move beyond volume production into high-value, smart fastening technologies.

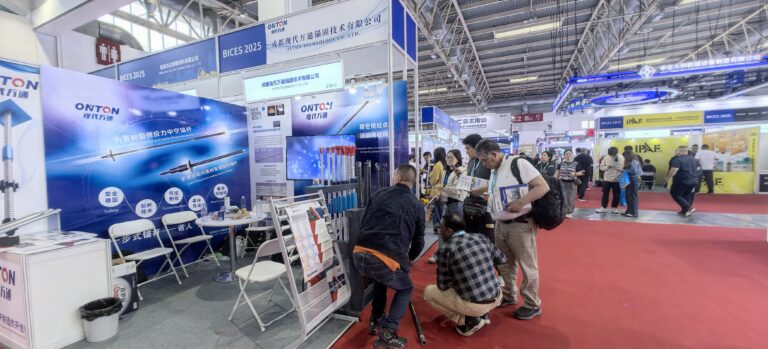

Onton’s Self-Drilling Hollow Bolt

A clear example of this commitment is Onton’s Built-in Resin Prestressed Self-Drilling Hollow Bolt. This bolt combines advanced engineering with full traceability as it has been designed for tunnelling, mining, and other underground reinforcement projects.

Each unit is manufactured under strict quality checks. They also come with complete production records, ensuring performance and accountability on-site. Its built-in resin anchoring system also reduces installation time, providing efficiency and reliability to its users.

Why This Matters for Global Buyers

For international buyers, working with China bolt manufacturers who prioritize quality and accountability will stop you from buying low-quality products. Chinese bolt manufacturers ensure compliance with international standards, reduce downtime caused by faulty parts, and provide confidence that every shipment is consistent with the last.

Conclusion

China’s bolt manufacturers are showing that quality and accountability can coexist by producing and supplying high-quality bolts to demanding field applications.

Products like Onton‘s self-drilling hollow bolt show how the company’s creativity, reliability, and quality assurance are influencing the future development of fasteners. China continues to be a top supplier of reliable bolt solutions for companies looking for high-quality bolts.