When it comes to underground construction, ensuring structural stability is crucial. One of the most reliable methods for tunnel support in modern engineering is the use of self drilling rock bolts. These systems offer both speed and strength, making them ideal for complex geological conditions.

What Are Self Drilling Rock Bolts?

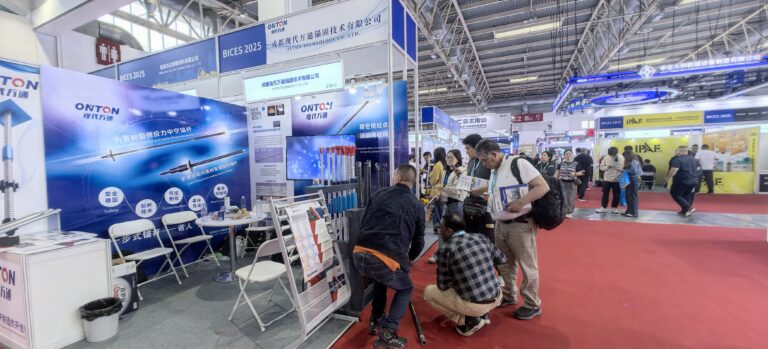

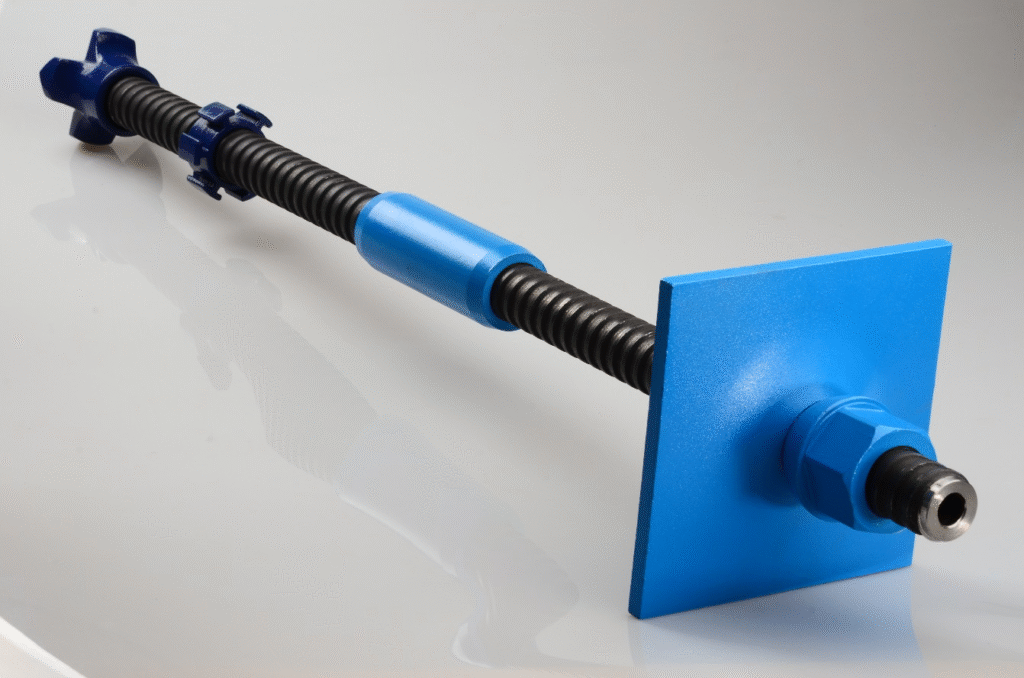

Self drilling rock bolts are distinguishable in that they combine drilling, grouting, and anchoring into a single operation. Unlike traditional anchoring systems, there’s no need for a pre-drilled hole. This makes them especially useful in weak or fractured ground where boreholes might collapse before support is installed. Ontonbolt offers a wide range of self drilling rock bolts that are tailored for various construction needs. Their hollow threaded bars act both as a drill rod and an anchor, reducing installation time significantly.

Why Are They Ideal for Tunnel Support?

In tunneling projects, working in unstable ground can be dangerous and time-consuming. Self drilling rock bolts improve safety by providing immediate tunnel support as they’re installed. The concave core of the bolt allows for pressure grouting, which fills girding voids and increases the relationship with the gemstone mass.. This not only reinforces the tunnel wall but also minimizes water ingress—a common issue in deep tunnel environments.

Their versatility is another advantage. Whether it’s soft clay, loose sand, or fractured rock, these bolts adapt well. Ontonbolt’s R25, R32, and R38 series offer different levels of load-bearing capacity and length, allowing engineers to select the right bolt for the project. With these options, tunnel designers can ensure that tunnel support is both efficient and cost-effective.

Practical Applications in the Field

Self drilling rock bolts are widely used in railway and highway tunnels, mining shafts, hydroelectric projects, and urban underground developments. In urban tunneling, for example, minimizing surface disruption is key. These bolts allow for faster progress and less noise, making them suitable even in densely populated areas.

Ontonbolt’s products come with accessories like couplers, nuts, and plates, which streamline the installation process. Their bolts can also be customized to fit unique tunnel geometries and rock conditions. This kind of adaptability is essential for projects that require high-precision tunnel support.

Best Practices for Installation

To ensure the effectiveness of self drilling rock bolts, it’s important to follow proper installation steps. First, select the correct bolt type and diameter based on ground conditions. Next, use an applicable drill carriage to advance the bolt to the needed depth.

Once in place, pressure grout through the hollow bar until resistance increases, indicating that surrounding voids have been filled. This forms a solid anchor and contributes to long-term tunnel support.

Regular inspection and load testing after installation are also recommended, especially in high-stress zones.

Final Thoughts

As tunnel projects become more ambitious, the demand for reliable and fast tunnel support systems grows. Self drilling rock bolts, such as those from Ontonbolt, offer a practical solution that saves time while enhancing safety. Their multifunctional design makes them an essential tool for engineers working below the surface.