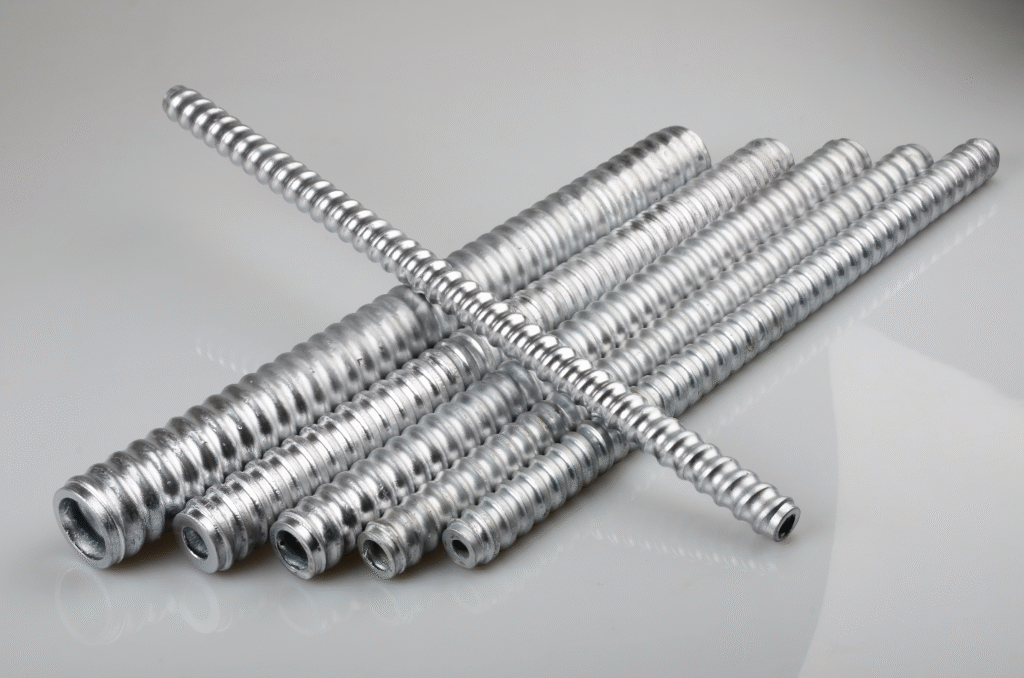

Galvanized Self-Drilling Anchor Hollow Bars

Corrosion protected Self-Drilling Anchor hollow bars. Galvanized in accordance with EN ISO 1461:1999.

Self Drilling Hollow Bar can be protected against corrosion in a variety of ways suitable for both temporary (<24 months) and permanent (>24 months) applications.

Galvanizing Standards: Self-drilling anchor hollow bars can be protected against corrosion by hot dip galvanizing in accordance with ASTM A-153 or EN ISO 1461:1999.

The coated Zinc is common and relatively cheaper. While the steel is in the kettle, the iron in the steel reacts with the molten zinc to form a tightly-bonded alloy coating that provides superior corrosion protection to steel.

Hot-dip galvanizing protects steel catholically similarly to the sacrificial anode method.

The thickness of zinc coating should be strictly controlled to ensure the specification of threads. In most cases, the female thread dimensions of nuts or couplers should be larger than usual. And this may reduce the load carrying capacity.

You can read the technical article Micropile Reinforcing System and Corrosion Protection for further understanding.

Share

Galvanized Anchor Rods and Self Drilling Hollow Anchor Bars

When facing harsh ground conditions or corrosive environments, galvanized anchor rods become the go-to solution for structural reinforcement. These rods are treated with an HDG (hot-dip galvanized) coating following EN ISO 1461:1999 standards, giving them a strong shield against weather and chemical exposure. The zinc layer forms a tight bond with the steel, making the rods ideal for both short-term projects and permanent installations. Whether anchoring into rock or stabilizing a slope, the superior strength and corrosion resistance of these rods extend the life of any construction.

When facing harsh ground conditions or corrosive environments, galvanized anchor rods become the go-to solution for structural reinforcement. These rods are treated with an HDG (hot-dip galvanized) coating following EN ISO 1461:1999 standards, giving them a strong shield against weather and chemical exposure. The zinc layer forms a tight bond with the steel, making the rods ideal for both short-term projects and permanent installations. Whether anchoring into rock or stabilizing a slope, the superior strength and corrosion resistance of these rods extend the life of any construction.

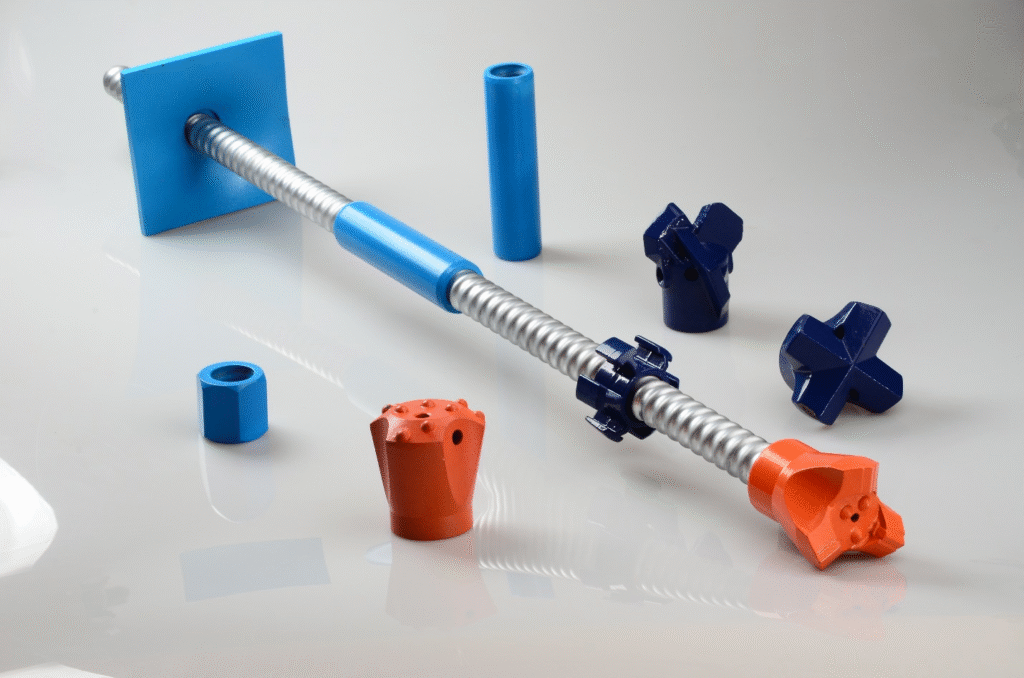

Product Features: Using Self Drilling Hollow Anchor Bars

The advanced design of self drilling hollow anchor bars offers ease of installation and high performance. Here are the key features:

The advanced design of self drilling hollow anchor bars offers ease of installation and high performance. Here are the key features:

- Dual thread compatibility: Supports both R thread and T thread types for versatile use across systems.

- Integrated drilling and grouting: Enables simultaneous operations, reducing labor and project time.

- Robust HDG coating: Shields the bars from rust and chemical attack, even in marine or chloride-rich zones.

- Hollow injection bar system: The hollow core allows grout to flow through directly, ensuring strong bonding and effective void filling.

- Controlled zinc thickness: Maintains thread integrity for secure coupling with nuts or plates.

These features work together to meet the practical needs of modern civil engineering.

How Self Drilling Hollow Anchor Bars Work

The operation of a self drilling hollow anchor bar starts with attaching a drill bit to the tip of the bar. As the rod rotates and drills into the substrate, grout is pumped through the center cavity. This allows both anchoring and grouting to occur in a single, seamless operation. The process minimizes equipment shifts and is especially useful in confined areas like tunnel faces or unstable slopes. When used as a hollow injection bar, the system ensures complete coverage and ground bonding without delay.

The operation of a self drilling hollow anchor bar starts with attaching a drill bit to the tip of the bar. As the rod rotates and drills into the substrate, grout is pumped through the center cavity. This allows both anchoring and grouting to occur in a single, seamless operation. The process minimizes equipment shifts and is especially useful in confined areas like tunnel faces or unstable slopes. When used as a hollow injection bar, the system ensures complete coverage and ground bonding without delay.

Advantages and Applications of Hollow Injection Bar Systems

These systems offer notable advantages:

These systems offer notable advantages:

- Time-saving process: Combines drilling, anchoring, and grouting in one setup.

- High adaptability: Works in loose soils, fractured rock, and areas requiring reinforcement.

- Strong corrosion resistance: The HDG coating gives confidence for long-term stability.

Applications for the hollow injection bar include:

- Slope stabilization and excavation walls

- Tunnel face stabilization and radial bolting

- Foundations for wind turbines and bridge abutments

- Avalanche barriers and retaining systems

- Injection works for void filling or soil improvement

Applocations

| Civil Engineering | Underground Mining and Tunneling |

| 1. Pile foundation | 1. Stabilization of tunnel portals, trenches, and cut-and-cover areas |

| 2. Slope and embankment stabilization | 2. Forepoling |

| 3. Reinforcement of excavation pits and retaining walls | 3. Face stabilization |

| 4. Foundation of pylons and wind mills | 4. Radial rock bolting |

| 5. Anchorage of avalanche protection structures and noise barriers | 5. Roof and rib bolting |

| 6. Injection works | 6. Injection works |

Why Choose Our Galvanized Anchor Rods and System

Each of the galvanized anchor rods goes through strict galvanization and quality inspection processes. The coating not only meets ISO and ASTM standards but is also optimized to preserve thread geometry. We offer tailored solutions to fit specific site requirements, including customized lengths, coupler adjustments, and bit selection. Our team guides product pairing, such as using these bars with grout pumps or rock drilling rigs.

As a reliable galvanized anchor rod supplier, we provide technical support and guidance from selection to deployment. Our rods and systems have been used in dozens of successful geotechnical, civil, and mining projects globally.

Product Relate