Rope Thread Self Drilling Hollow Bar

Rope/ R thread was first invented by MAI in the 1960s to solve the low construction speed on complicated underground works. R thread is designed and produced according to ISO 10208 (R25, R32, R38) and ISO 1720 (R51). The thread is usually left-handed.

R thread anchor bar can be connected and installed quickly in the loose or collapsing stratums, which could be drilling and grouting in one step.

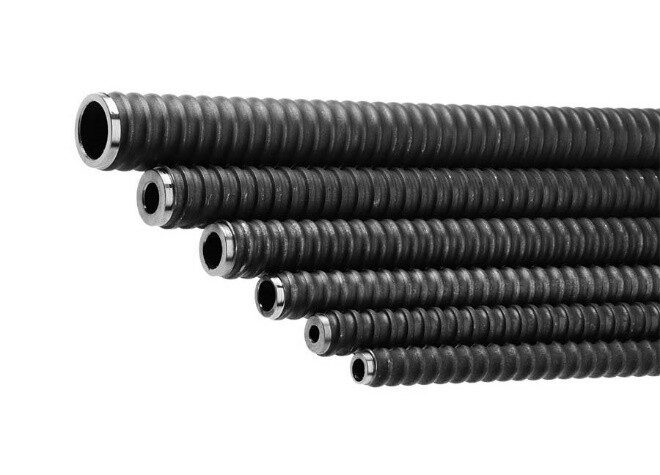

Rope Threaded Hollow Bars

Thread Profile: All rope thread, commonly referred to as fully rope threaded, continuously threaded. The Rope Thread is according to ISO 10208

Steel Material: C45E/S460NH

Surface Treatment: Galvanized or Epoxy coating when necessary.

Others: Chamfered, stamped or color coded for grade identification when necessary.

Share

ROPE THREAD IBO BARS TECHNICAL DATA

| R25 | R32L | R32N | R32S | R32SS | R38 | R51L | R51N | |

|---|---|---|---|---|---|---|---|---|

| Average Inner Diameter | 12.0 mm | 21.5 mm | 20.5 mm | 17.0 mm | 15.0 mm | 22.0 mm | 39.0 mm | 34.0 mm |

| Cross-Sectional Area | 300 mm² | 304 mm² | 365 mm² | 440 mm² | 520 mm² | 610 mm² | 700 mm² | 990 mm² |

| Yield Load | 150 kN | 160 kN | 230 kN | 280 kN | 330 kN | 400 kN | 450 kN | 630 kN |

| Ultimate Tensile Load | 200 kN | 210 kN | 280 kN | 360 kN | 400 kN | 500 kN | 550 kN | 800 kN |

| Yield Stress | 500 Mpa | 526 Mpa | 630 Mpa | 640 Mpa | 630 Mpa | 650 Mpa | 640 Mpa | 640 Mpa |

| Ultimate Stress | 670 Mpa | 690 Mpa | 770 Mpa | 820 Mpa | 770 Mpa | 820 Mpa | 790 Mpa | 800 Mpa |

| Weight | 2.30 kg/m | 2.60 kg/m | 2.90 kg/m | 3.40 kg/m | 4.10 kg/m | 4.75 kg/m | 5.60 kg/m | 7.70 kg/m |

| Elongation Agt | > 5% | > 5% | > 5% | > 5% | > 5% | > 5% | > 5% | > 5% |

Enhance Stability and Security with ONTON’s Superior R-Type Threaded Bar Anchors

In construction and civil engineering, ensuring stability and security is paramount. Choosing anchoring solutions can make all the difference for building foundations, retaining walls, or other structural applications. ONTON, a leading provider of construction and engineering solutions, offers a range of superior products designed to enhance stability and security, including R-Type threaded bar anchors.

ONTON’s Wholly-owned R&D Center

ONTON has strong R&D capabilities and the ability to transform technology into productivity. Self-drilling anchor bars can achieve drilling and grouting in one step to greatly reduce installation time.

- Drilling. Use a trolley or drilling rig to drill the anchor rod connected to the drill bit to the designed depth.

- Grouting. Remove the drilling rig, install the grout stopper, 25cm away from the hole. Connect the exposed end of the anchor rod to the grouting machine through a quick grouting joint. Start the machine to grout.

- Stop the grouting machine when the grouting is full and the pressure reaches the design value. The grouting pressure is determined based on the design parameters and grouting machine performance. Water-cement ratio reference value: (0.35~0.45):1.

- Install backing plate and nut to lock the anchor rod according to design.

R-Type Threaded Bar Anchors: Unmatched Security

ONTON’s R-Type threaded bar anchors are engineered to provide unmatched security in construction projects. These anchors are designed to resist tension forces and are well-suited for various applications, including structural support and reinforcement.

- High Tensile Strength: Crafted from premium materials, ONTON’s R-Type threaded bar anchors boast exceptional tensile strength. This characteristic makes them ideal for applications where security and structural integrity are paramount.

- Easy Installation: ONTON’s R-Type threaded bar anchors are designed with easy installation in mind. This user-friendly feature not only saves valuable time but also reduces labor costs. They are versatile and can be used in various construction scenarios, from building projects to bridge construction.

- Corrosion Resistance: Durability is a crucial factor in construction, and ONTON’s threaded bar anchors are engineered with corrosion resistance in mind. They offer a long service life, even in challenging environments where exposure to moisture and other corrosive elements is a concern.

Features of Self Drilling Threaded Anchors

- With R thread (ISO 10208 & ISO 1720) and T thread (T international standard), the anchor bar could be left hand or right hand thread. R thread and most T thread hollow bars usually left hand, and T73 anchor bar is right hand thread. But the thread direction could be customized according to customers’ requirements.

- Special heat treatment technology to improve anchor bar’s strength without changing the internal diameter and unit weight of the anchor rod.

- Roll forming technology to form full-length threads on the anchor rods surface. With various components, to realize the integration of drilling, grouting, anchoring and other functions.

The anchor rods no need to be pulled out, and the hollow space could be used as a grouting channel for grouting from the inside to the outside.

The Power of R-Type Soil Screw Anchors

R-type soil screw anchors, often referred to as helical anchors or screw piles, have revolutionized foundation solutions in construction. ONTON’s soil screw anchors are engineered with precision and made from high-quality materials to deliver outstanding performance.

- Enhanced Stability: ONTON’s soil screw anchors are designed to penetrate the soil deeply, providing exceptional stability and load-bearing capacity. This makes them suitable for various soil conditions, ensuring reliable support for various applications.

- Quick and Cost-Effective Installation: Installing ONTON’s soil screw anchors is a swift and straightforward process, significantly reducing project timelines and costs. Its innovative design requires minimal excavation, saving both time and resources.

- Environmentally Friendly: In an era of environmental awareness, ONTON’s R-type soil screw anchors stand out as an eco-friendly alternative to traditional concrete foundations. They can be easily removed and reused, reducing waste and minimizing the carbon footprint associated with construction projects.

Applications, Installation, and Surface Treatment Options

ONTON’s R-Type threaded bar anchors find applications in a wide range of construction scenarios, including residential, commercial, and industrial projects. They are suitable for foundations, retaining walls, stabilization, and structural reinforcement.

Installation of these anchors is straightforward, typically involving drilling or screwing them into the ground or structures. ONTON provides comprehensive installation guides to ensure proper and efficient setup.

Surface treatment options are available further to enhance the durability and aesthetics of these products. Depending on your project’s requirements, you can choose from various surface treatments, including galvanization and epoxy coatings, to protect against corrosion and provide an attractive finish.

ONTON’s Commitment to Excellence

ONTON is dedicated to providing top-notch construction solutions, and its R-Type threaded bar anchors are no exception. These products are backed by extensive research and development, ensuring they meet and exceed industry standards for safety and performance.

With ONTON’s products, you can enhance stability and security in your construction projects, whether building a residential home, a commercial complex, or a critical infrastructure project. Its soil screw anchors and R-Type threaded bar anchors are reliable choices that professionals have trusted in the field for years.

Product Relate