Stainless Steel IBO Self-Drilling Anchor

Stainless IBO Anchor Bolt is a good reinforcing material to be used for permanent support works.

It provides the optimum combination of strength bond and corrosion resistance suitable for any rock bolt or ground anchor application.

Applications include: Support of water diversion tunnel, Permanent soil nailing timbering, Slope support, etc.

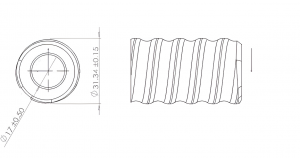

Stainless IBO Anchor Common Types: R25, R32, R38

Share

Stainless IBO Anchor Bolt Technical Data

| Technical Data | |

|---|---|

| Steel Garde | AISI 316 stainless |

| Elongation | 20% |

| Typical lengths | 3000 mm, other lengths on request |

| Thread | ISO 10208, T thread on request |

Stainless IBO Anchor Bolt Technical Data

| Anchor Bolt Size | R25 | R32 | R38 |

|---|---|---|---|

| Outer Dia. (mm) | 24.74±0.15 | 31.34±0.15 | 37.99±0.15 |

| Inner Dia. (mm) | 12±0.5 | 17±0.5 | 19±0.5 |

| Ultimate Strength (kN) | 200 | 320 | 400 |

| Nominal Weight (kg/m) | 2.5 | 3.6 | 5.3 |

High-Performance Self Drilling Anchors

Self drilling anchors join drilling, grouting, and anchoring in one smooth move. The system cuts project time because crews drill, grout, and fix the bar in a single pass. Onton shapes each bar from AISI 316 stainless steel. The metal resists rust, handles salt spray, and holds its shine. A clear cut thread grips grout tight, while the IBO hollow bar lets grout flow through the center tube and seal every rock joint. On slopes, tunnels, and sea walls, these anchors act fast, bond strong, and stay in place for decades.

IBO Hollow Bar Operation Process

Work starts with a rig holding a sacrificial drill bit. The bit threads onto the IBO hollow bar. As the rod turns, grout pumps through the bar and exits ports in the bit. The fluid cools the bit, flushes cuttings, and fills cracks as drilling moves forward. When the hole reaches depth, the bit stays put as part of the anchor. Crews add couplers to extend bars in soft zones. Once grout sets, the stainless IBO anchor bolt creates a solid bond from face plate to rock. The process avoids casing, shortens rig time, and keeps boreholes open in loose soils. For busy sites needing quick lanes clear, this streamlined step matters.

Stainless IBO Anchor Bolt Features

Not needed. The anchor is mechanical. Site power limits never slow work.

Each stainless IBO anchor bolt shows ultimate strength up to 400 kN, enough for hard rock pulls.

Skip them. Here, the long life sits in steel. A 20 percent elongation rating absorbs shock from shifting ground.

Surface glare stays low, so inspectors spot cracks early.

Crews pick R25, R32, or R38 to match load plans without cutting bars on site.

IBO Hollow Bar Applications

- Tunnel Linings: In tunnel construction, the IBO hollow bar efficiently transfers ground pressure to stable strata while simultaneously sealing voids through pressure grouting. This dual function minimizes water ingress and supports long-term structural integrity.

- Permanent Soil Nailing: Self-drilling anchors provide reliable reinforcement for steep slopes and excavation walls by penetrating various soil types without the need for casing. When combined with mesh and shotcrete, they create a durable, load-bearing system suitable for permanent slope stabilization.

- Coastal Slope Support: Salt spray corrodes plain steel fast. A stainless IBO anchor bolt provides strong resistance against chloride-induced corrosion, making it well-suited for long-term performance in coastal and marine environments.

- Wind Turbine Bases: Wind turbine foundations are subject to constant dynamic loading. The high elongation capacity of the IBO hollow bar makes it particularly suitable for absorbing and distributing these cyclical stresses.

Benefits of Self Drilling Anchors in Diverse Soils

Projects choose self drilling anchors for their speed, strength, and clean installation. The open-center design lets grout seal voids and block water, so frost heave and flow paths lose force. Stainless steel fights corrosion in coastal air or de-icing chemical zones. The system adapts to tight heads because no extra casings or rods clutter the drill deck. With fewer moves, crews lower accident risks and noise. Owners save on equipment hire, and surrounding traffic sees less delay.

Why Choose Onton for Stainless IBO Anchor Bolt Solutions?

Onton manufactures stainless IBO anchor bolts using certified AISI 316 steel and adheres to ISO 9001 and ISO 10208 standards to ensure consistent quality. Each product is tested for performance, supported with clear technical documentation, and available in both standard and custom lengths to meet diverse project needs. With a focus on durability, compliance, and responsive service, Onton offers dependable self drilling anchor solutions for demanding ground engineering applications.

Product Relate