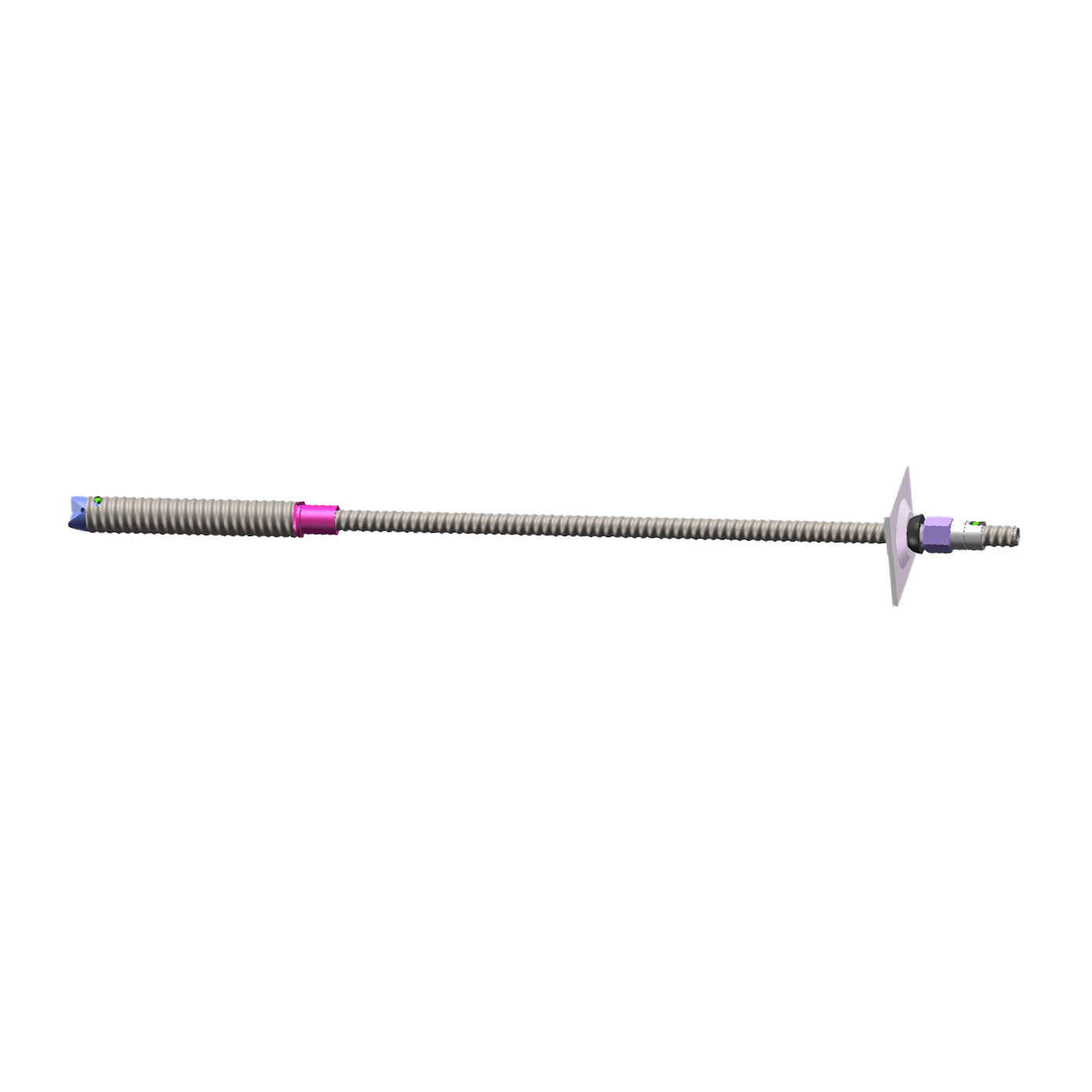

T-thread Self Drilling Hollow Bar

T thread is designed and produced according to T International Standard, and the rod anchor types are: T30, T40, T52, T73, T76, T103. T thread makes itself good bond to the accessories or rotary drill rigs. Its high strength makes it widely used in deep foundation, slope stabilization, tunnel, mine or other geological disaster areas.

If the rib height increases or the number of ribs per unit length increases, the relative rib area increases. The rib area fR is used as a parameter for the bonding quality of T thread anchor bolts, and the optimal value is fR = 0.21 - fR = 0.33.