There are many kinds of self drilling hollow bar steel grades globally, the more common ones are 28Mn6, 41Cr4 (40Cr), J55 (37Mn5), N80, S45E (45#), S355N (Q355B), S460N, etc. In fact, the material requirements of SDA should be selected according to the specific application conditions and the factory’s processing technology.

There are many kinds of self drilling hollow bar steel grades globally, the more common ones are 28Mn6, 41Cr4 (40Cr), J55 (37Mn5), N80, S45E (45#), S355N (Q355B), S460N, etc. In fact, the material requirements of SDA should be selected according to the specific application conditions and the factory’s processing technology.

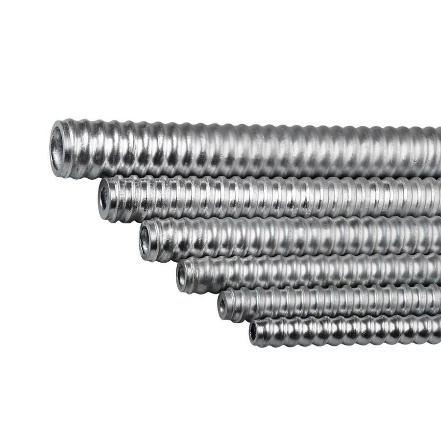

R & T self drilling anchor bar

The application of self drilling hollow bar is mainly in three fields: rock bolt, soilnail and micropile. The standards applicable to self drilling anchor bar in different applications are different.

- Rock bolt: ASTM F432 <Standard Specification for Roof and Rock Bolts and Accessories1>

- Soilnail: BS EN 14490 <Execution of Special Geotechnical Works-Soil Nailing>; FHWA-NHI-14-007 <Soil Nail Walls Reference Manual>

- Micropile: BS EN 14199 <Execution of Special Geotechnical Works-Micropiles>; FHWA NHI-05-039 <Micropile Design and Construction>

For rock bolt, welding is basically not involved in its application, so there is no requirement for the welding performance of the steel material. For soilnail and micropile, welding may be used in the installation, so the welding performance of the steel must be considered according to the actual situation.

All the above steel grades are suitable for rock bolt, while S355N and S460N are more suitable for soilnail and micropile.

When customers choose and compare self drilling anchor bar, they may choose the approximate steel grades according to the project design and the installation stratum. It also can choose the steel grade according to factory’s manufacture technology.

The following is a brief description of the characteristics of steel grades by different processes:

1. If self drilling anchor bolt is processed by cold rolling, the finished product is in a state of cold hard, the steel usually contains Mn alloy, such as 28Mn6, 37Mn5, J55, N80, etc. Mn alloy has a high strength of work hardening and can obtain a higher strength anchor bolt through cold extrusion. The disadvantage of this process is that it may lead to poor plasticity of anchor bolt.

2. If self drilling anchor bolt is processed by warm rolling, the finished product is in a state of metal stress recovery, which allows the anchor bolt to retain a higher plasticity. 28Mn6, 40Cr, 37Mn5, J55, N80, and S45E are applicable to this process. The disadvantage is that the strength of anchor bolt is not too high.

3. If self drilling anchor bolt is processed by hot rolling, the finished product is in a state of heat treatment. According to different steel grades, different heat treatment methods can obtain excellent performance of anchor bolt. All of the above mentioned steel grades can be used with this process. The disadvantage is that the process is more complicated and difficult, and most factories cannot master this technology.

Common questions about SDA materials:

1. Does self drilling anchor bar with the same steel grade has the same quality?

Anchor bar is manufactured by the same steel grade, the performance of anchor bar may be very different with different processing.

2. Is the anchor bar manufactured by alloy steel (such as 40Cr, 28Mn6, etc.) with higher quality than that by low alloy steel (such as S355N, S460N, etc.) and high-quality carbon steel (such as C45, etc.)?

No, steel grade is only one of the factors to affect the performance of anchor bar. The factory manufactures anchor bar with good performance based on customer’s requirement, which has little to do with whether alloy steel is selected.