YouTube video: https://youtu.be/kzeRktj0NE4

On April 15th, 2024, leaders of the National Railway Group went to the exit of Gayi Tunnel to observe the construction of the anchoring and injection machine. The R25 built-in resin prestressed self drilling hollow bolt jointly developed by ONTON and the Railway Construction Research Institute was used for rapid anchoring.

1. Observe on-site the construction of a double-arm integrated machine, with one anchor rod, drilling, pushing anchor rods, stirring until the strength increases, pull-out and locking grouting, all fully mechanized;

2. Detailed introduction to the construction process of built-in resin anchors;

3. Simulate different test scenarios under multiple working conditions, form an automated and standardized control process, plan the trajectory and division of labor of the two arms, and realize construction by one person;

4. The R&D staff reported on the research and development progress of the automated construction of the anchor injection all-in-one machine, which enables one operator to operate multiple equipment, thereby reducing labor costs;

5. To further simplify the anchor construction process, China Railway No. 8 Bureau will take the lead in cooperating with the anchor manufacturer (ONTON) and China Railway Equipment to simplify the anchor construction process and improve the efficiency of anchor construction;

6. The operator was asked on-site about the use of the double-arm anchoring and injection machine. The operator answered that the double-arm anchoring and injection machine has higher construction efficiency than the single-arm machine;

ONTON R25 built-in resin prestressed hollow bolt have passed Railway Construction Research Institute’s laboratory and field tests, and have now begun mass production and are being constructed and installed in most large tunnels in China. They will also be popularized in mining and other fields in the future.

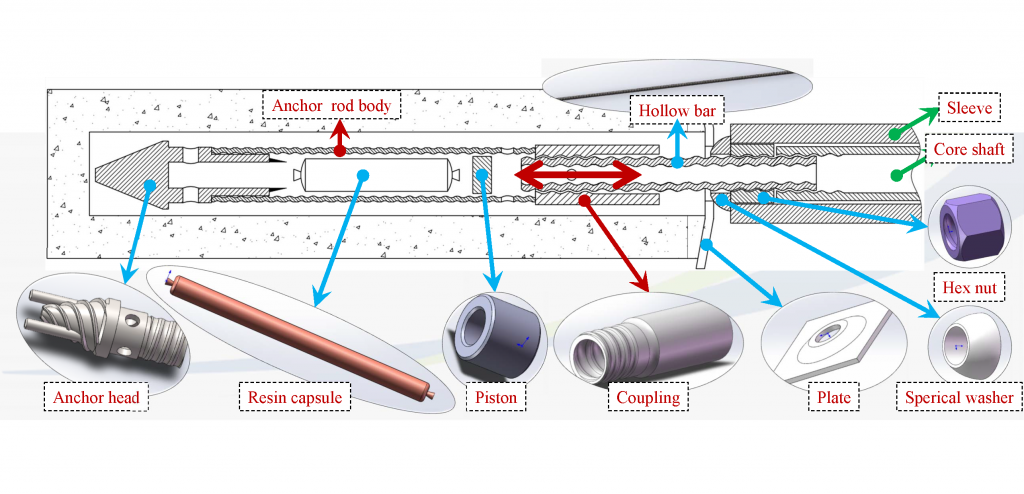

Build-in Resin Prestressed Self Drilling Hollow Bolt mainly consist of the components in the following picture.The anchor head is similar to a drill bit and can be rotated and pushed into the collapsed hole formation; the rod body of the anchoring section protects the resin capsule from being scratched; the piston pushes the capsule out of the anchor head; the rod body of the anchoring section is also used to rotate and stir the resin; the hollow rod body doubles up as grouting pipe. Resin could be setting from several seconds to several minutes, which largely shortens the setting time and installation time compared with concrete grouting. It is also cleaner.

For video viewing, please click https://youtu.be/kzeRktj0NE4