products

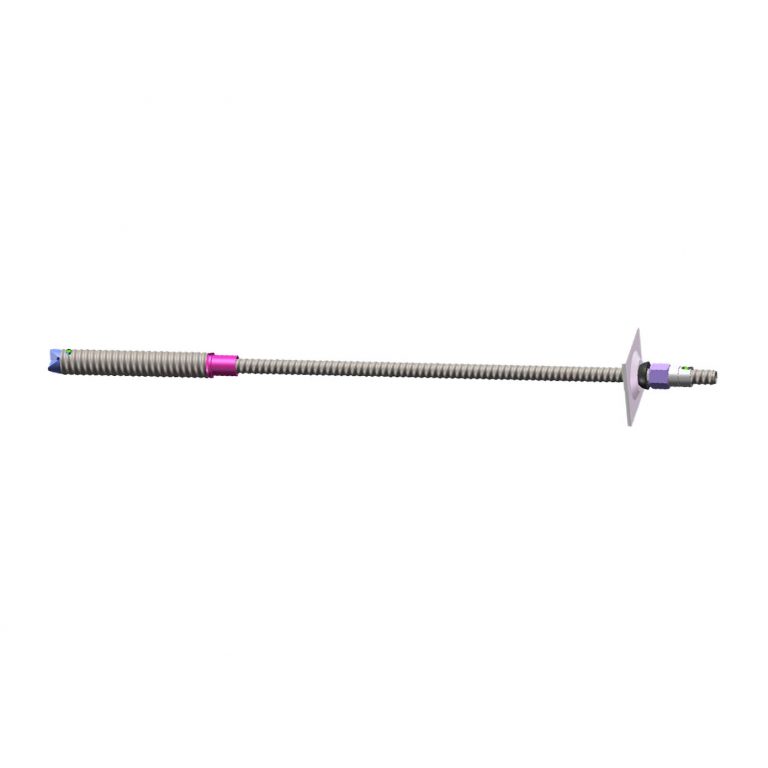

Anchor Coupler

Coupler |

OutsideDiameter(mm) |

Length(mm) |

Hardness |

Material |

Unit Weight(Kg/pc) |

ThreadType |

| R25 | 36 | 150 |

HRC 20-30 |

40Cr/ C45 |

0.70 |

R thread |

| R32 | 42 | 160 | 0.82 | |||

| 190 | 1.00 | |||||

| R38 | 51 | 180 | 1.40 | |||

| 220 | 1.72 | |||||

| R51 | 63 | 200 | 1.85 | R thread ISO 1720 Left hand |

||

| Options of Anti-corrosion | Painting or anti-rust oil Hot-dipped galvanization (HDG), EN ISO 1461:1999 Epoxy coating, ISO 14654:1999 HDG + Epoxy |

|||||

Anchor Nut

Nut |

Key Size(mm) |

Length(mm) |

Hardness |

Material |

Unit Weight(Kg/pc) |

ThreadType |

| R25 Hex Nut | 41 | 41 |

HRC 20-30 |

40Cr/ C45 |

0.29 |

R thread |

| R25 Domed nut | 41 | 0.31 | ||||

| R32 Hex Nut |

46 |

45 | 0.35 | |||

| 65 | 0.60 | |||||

| R32 Domed Nut | 45 | 0.45 | ||||

| 65 | 0.70 | |||||

| R38 Hex Nut | 50 | 60 | 0.48 | |||

| R38 Domed Nut | 55 | 65 | 0.85 | |||

| R51 Hex Nut | 75 | 70 | 1.60 | R thread ISO 1720 Left hand |

||

| R51 Domed Nut | 70 | 1.70 | ||||

| Options of Anti-corrosion | Painting or anti-rust oil Hot-dipped galvanization (HDG), EN ISO 1461:1999 Epoxy coating, ISO 14654:1999 HDG + Epoxy |

|||||

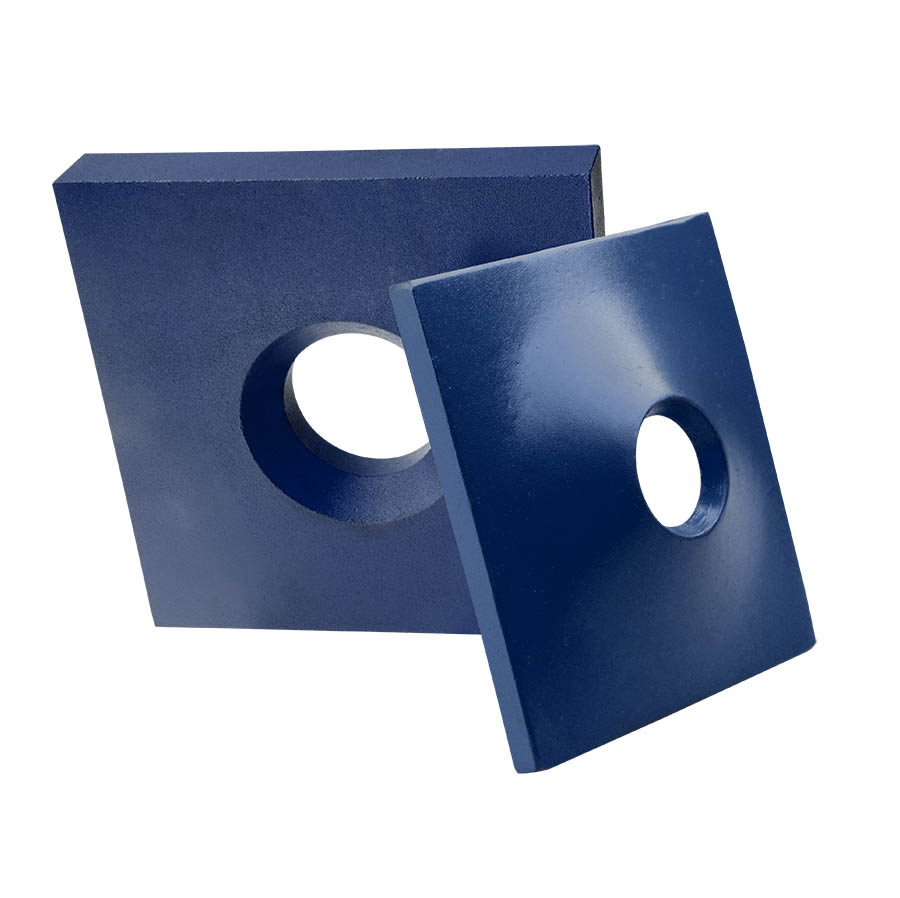

Anchor Plate

Plate |

Dimension(mm) |

Thickness(mm) |

Hole Diameter(mm) |

Material |

Unit Weight(Kg/pc) |

| R25 | 150 X 150 | 8 | 30 | Q235B/ Q345B | 1.40 |

| R32L, R32N | 150 X 150 | 8 |

35 |

1.40 | |

| R32S | 200 X 200 | 8 | 2.50 | ||

| R32SS | 200 X 200 | 10 | 3.10 | ||

| R38 | 200 X 200 | 12 | 41 | 3.70 | |

| R51 | 200 X 200 | 16 | 60 | 4.90 | |

| Options of Anti-corrosion | Painting or anti-rust oil Hot-dipped galvanization (HDG), EN ISO 1461:1999 Epoxy coating, ISO 14654:1999 HDG + Epoxy |

||||

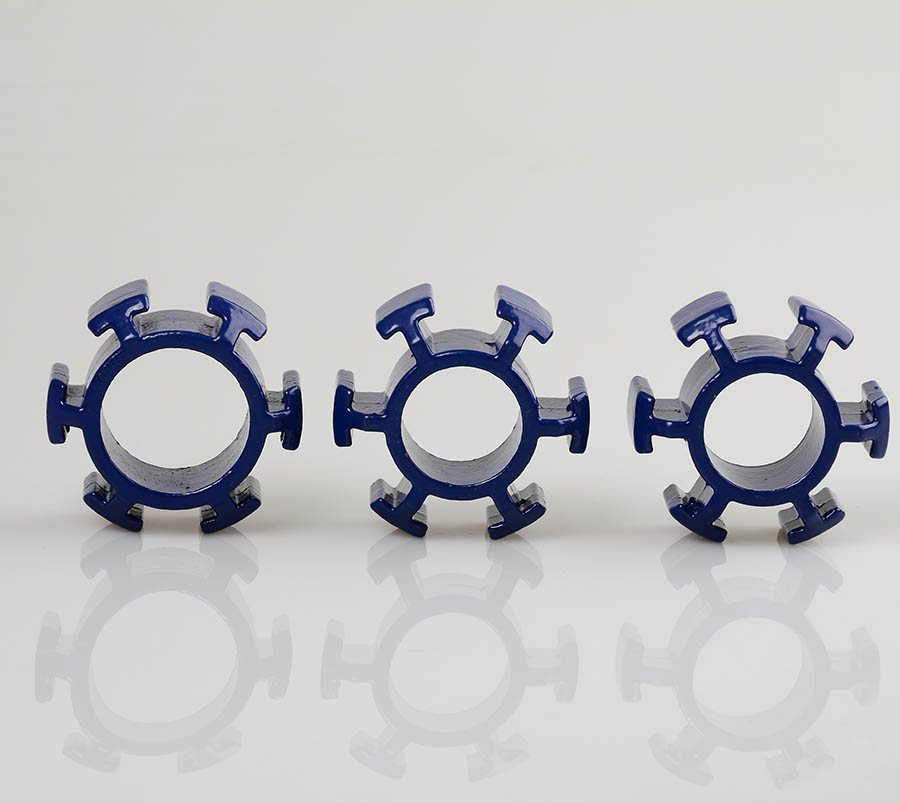

Centralizer

Ccentralizer |

Outside Diameter(mm) |

Length(mm) |

Material |

Unit Weight(Kg/pc) |

| R25 |

70 |

35 |

ZG45 |

0.35 |

| R32 | ||||

| R38 | ||||

| R51 | 85 | 40 | 0.52 |

Anchor Drill Bits

Drill Bit Type |

Hollow Bar Type |

Outside Diameter(mm) |

Hardness |

Material |

ThreadType |

Stratum Type |

|

EX |

R25 | 42, 51 |

HRC 49-54 |

42CrMo |

R thread ISO 10208 ISO 1720 Left hand |

Loose to medium dense ground conditions |

| R32 | 51, 76, 90 | |||||

| R38 | 76, 90, 110 | |||||

| R51 | 90, 115, 130 | |||||

|

EXX |

R25 | 42, 51 |

HRA 87-89 |

40Cr + YG9C |

R thread ISO 10208 ISO 1720 Left hand |

Soft to medium rock formations |

| R32 | 51, 76, 90 | |||||

| R38 | 76, 90, 110 | |||||

| R51 | 90, 115, 130 | |||||

|

ES |

R25 | 42, 51 |

HRC 49-54 |

42CrMo |

R thread ISO 10208 ISO 1720 Left hand |

Unconsolidated rock with boulders |

| R32 | 51, 76, 90 | |||||

| R38 | 76, 90, 110 | |||||

| R51 | 90, 115, 130 | |||||

|

ESS |

R25 | 42, 51 |

HRA 87-89 |

40Cr + YG9C |

R thread ISO 10208 ISO 1720 Left hand |

Medium to hard rock formations |

| R32 | 51, 76, 90 | |||||

| R38 | 76, 90, 110 | |||||

| R51 | 90, 115, 130 | |||||

|

EW |

R25 | 76 |

HRC 49-54 |

42CrMo |

R thread ISO 10208 ISO 1720 Left hand |

Optimized geometry for very soft to soft caly |

| R32 | 76, 90, 110 | |||||

| R38 | 76, 90, 110 | |||||

| R51 | 90, 115, 130 | |||||

|

EY |

R32 | 76, 90 |

HRC 49-54 |

42CrMo |

R thread ISO 10208 ISO 1720 Left hand |

Loose to medium dense ground conditions |

| R38 | 76, 90, 110 | |||||

| R51 | 90, 115, 130 | |||||

| EYY Carbide drop centre bit |

R32 | 76, 90 |

HRA 87-89 |

40Cr + YG9C |

R thread ISO 10208 ISO 1720 Left hand |

Soft to medium rock formations |

| R38 | 76, 90, 110 | |||||

| R51 | 90, 115, 130 | |||||

| EC Steel arching bit |

R32 | 51, 76, 90 |

HRC 49-54 |

42CrMo |

Unconsolidated soil with small boulders |

|

| R38 | 76, 90, 110 | |||||

| R51 | 90, 115, 130 | |||||

| ECC Carbide arching bit |

R32 | 51, 76, 90 |

HRA 87-89 |

40Cr + YG9C |

R thread ISO 10208 ISO 1720 Left hand |

Soft to medium rock formations |

| R38 | 76, 90, 110 | |||||

| R51 | 90, 115, 130 | |||||

| Options of Anti-corrosion | Painting | |||||