Origin:

Origin:

The technique of soil nailing began in the 1970s.

It refers to the New Austrian Tunneling Method (NATM), which is a system for underground excavations in rock.

It has been successfully utilized worldwide for excavation support and slope stabilization, and its use is growing rapidly.

Introduction:

Most of the time, these anchors are created using bars inserted in a bore hole and held in place using grouting or a mechanical anchor. Their purpose is to improve the resistance of the ground.

Rock: rock bolts

Rock bolts are 15 to 32 diameter bars, inserted in 30 to 60 mm bore holes. They are generally between 3 and 6 meters long.

They may be bonded along their entire length by cement grouting or anchored at various points at the base of the hole using chemical resin or a mechanical anchorage.

Rock bolts transfer load from the unstable exterior to the confined (and much stronger) interior of the rock mass.

New Austrian Tunneling engineering and underground mining apply this anchor largely.

Applications:

In mines

The bolts reinforce the roof of the cavity to recreate a beam effect with the natural earth.

In tunnels

The bolts reinforce the natural earth on the roof to create an arched effect.

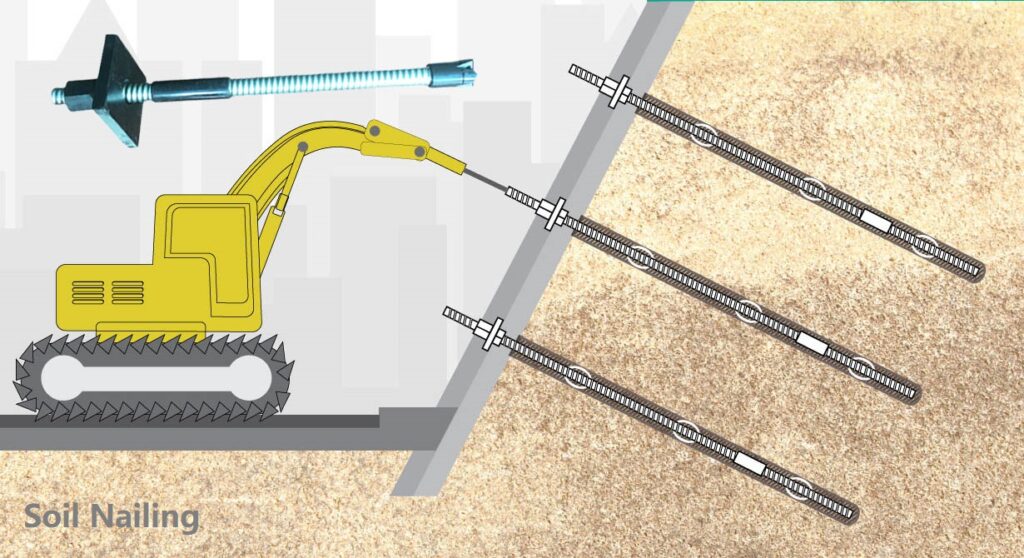

Soft ground: soil nails

Applying the principles of systematic rock anchoring to soil seems to be obvious, but the requirements for soil nailing are higher.

Soil nails are 20 to 50 mm diameter bars, inserted in 70 to 150 mm bore holes. They are generally over 6 meters long and may be as much as 30 meters.

Applications:

- Stabilization of excavations

- Embankment stabilization

- Stabilization and renovation of land slips

- Road construction

- Renovation of retaining walls, tunnels

Solid Bar and Hollow Bar

These two techniques above insert the reinforcing element (reinforced concrete) into the soil/rock mass. Both solid and hollow bars are available.

Solid bars are usually installed into the pre-drilled holes and then grouted into place using a separate grout line, whereas hollow bars may be drilled and grouted simultaneously by the use of a sacrificial drill bit and by pumping grout down the hollow bar as drilling progresses.

Applying for underground applications in unconsolidated soil/rock conditions, hollow bar is typically effective.

Furthermore, since the labor cost is higher and higher, hollow bar soil nails/rock bolts seem to be more economical.

Installation of Soil Nail

- Inserting Bar

- Spraying Shotcrete

- Applying Plate

- Spraying Shotcrete

Requirements:

Installation of a soil nail

For the site

Stable, self-supporting soil at the excavation face: by applying reinforced shotcrete.

Strong working space for placing drill rigs: by excavating in stages properly.

For the Soil Nail System

High tensile and shear strength

High ductility

High bond strength

Installation of a rock bolt

For the drilling equipment

Choose the appropriate drill rig according to the scale of works, work environments, ground conditions, size of self-drilling anchor and depth of drilling.

In some limited headroom and the rock bolt is smaller sizes like R25 (or R32 with short lengths), handheld equipment is also workable.

Drilling, flushing, grouting, and post-grouting

Components:

Load-bearing or functional elements

Hollow core anchor rods

Extension couplings

Hexagonal nuts/hex nuts

Plates (Domed or flat bearing plates)

Operational elements

Drill bits

Spacer/centralizer

About Onton All Threaded Hollow Bar

OntonBolt manufactures hollow anchor rods in all configurations from 1/2″ to 3″ diameter.

We offer self-drilling anchors and soil nails, and micropiles, which are the same as DYWIDAG Drill Hollow bars. The thread profile is Standard ISO rope thread (R25–R51). The main markets include India, Turkey, Australia, and America.

Additionally, we can provide assemblies with sleeves or coupling nuts.

OntonBolt also manufactures Trapezoidal Threaded (T30–T76) Hollow Bars to be an alternative to Ischebeck Titan anchor bolts. They are mainly exported to Russia, Europe, and America.

We can work to all specifications and can provide hot-dip galvanized drill rods.

We can manufacture items specific to customers’ requirements. We continually update and improve our products to meet the changing demands of customers and the industry.

The introduction below is about Soil Nailing work, explaining the usage of the nail, where it can be used, the nailing depth required, and guidelines for the installation of hollow bar anchors. In fact, soil nailing works are different from each other. It depends on the engineer’s design. Thus, the following introduction of soil nailing is for guidance only.