Introduction:

The core of the Onton Self-Drilling Anchor Bolt is a hollow, thick-walled, central drilling rod with a drill bit at the top. The system is modular, meaning that the most appropriate configuration can be put together to suit on-site circumstances and the forces that apply.

The self-drilling anchor bolts are available in the steel grade S460NH and other common types. All of steel materials are produced according to EN 10210-1 and have excellent capacity to the short time simultaneously dynamic loads (torque, frequent percussion impact, bending moments) during drilling as long-term load and durability.

Working Process:

The system is used to create anchors in soft or unstable ground. Drilling, positioning of the reinforcement and injection are carried out in a single operation, thereby avoiding the difficult task of drilling a casing hole.

A disposable drill bit is screwed onto the first rod. The steel hollow bar is then connected directly to the drill rig (if necessary using an injection swivel).

Drilling starts with simultaneous injection via the central hole in the bar. As the drill bit features a hole, the cement grout spreads into the ground as the drill moves forward.

When the first bar is fully inserted in the ground, injection and drilling are stopped, and the bar is unscrewed from the drill rig.

The second bar can then be coupled to the first bar and the machine, and operation can be resumed.

Features:

Fast drilling and grouting installation

Similar installation methods for all ground conditions

Ability to work with small drill rigs without casing in restricted headroom conditions

High standard of quality control from production stage to installation of the Self-Drilling Hollow Bar Anchor Bolt ensures consistent quality

High yield strength

Good impact strength

Good ductility

Excellent weldability

Our Onton Steel Drilling anchor Systems comply with the requirements of design following the US standards:

ASTM A615

ASTM F432

AASHTO M 31

FHWA-NHI-14-007(2015)

The Steel Hollow Bar Anchor Bolts can be customized to fulfill different requirements in different areas. And we offer a full-scale stock of all necessary components such as couplings, nuts, drill bits (for various soil conditions), centralizers, and plates.

Components:

Threaded hollow bars (all lengths)

Hollow Bars have a continuous external thread with an R (rope thread) or T (trapezoidal thread) profile.

Couplers

Flexibility in length by using couples. A specially designed stopping system ensures that the coupler is correctly positioned on the bars to be coupled.

Nuts and plates

The plates and nuts are used to create the anchor head. There are straight nuts and spherical nuts, each with their appropriate plates.

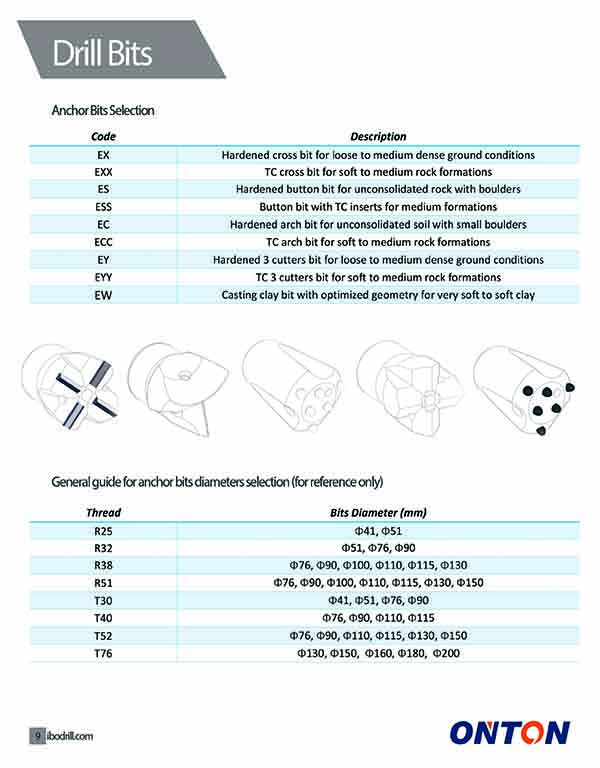

Drill bits

Choice of drill bits for different ground conditions.