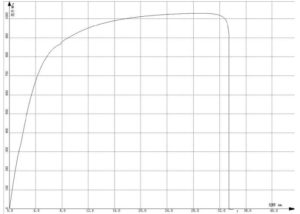

Hollow bar anchor manufacturers carry out tensile test to ensure the self-drilling anchor rods are strong enough. The values are plotted on a coordinate graph – with strain elongation along the x-axis and stress, typically in MPa, along the y-axis.

Figure 1 shows a typical tensile stress/strain curve.

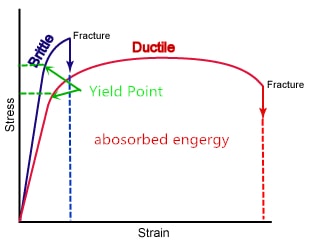

Figure 2. Tensile capacity from self-drilling anchor tensile curve

For small strains, the curve is actually linear. The change in the self-drilling anchor hollow bar in this region is referred to as elastic, because when the stress is removed the object returns to its original length.

After the steel material strains a certain amount, it reaches its yield point. At this point the slope of the curve decreased drastically and ceases being linear, and deformations to the hollow drill bar become permanent. This is an important distinction between different hollow bar anchors.

According to the test standards, the self-drilling anchor hollow bar specimen should be 500 to 2000 mm in length. Tensile test result would be fairly inaccurate and even invalid if the specimen length is too short.

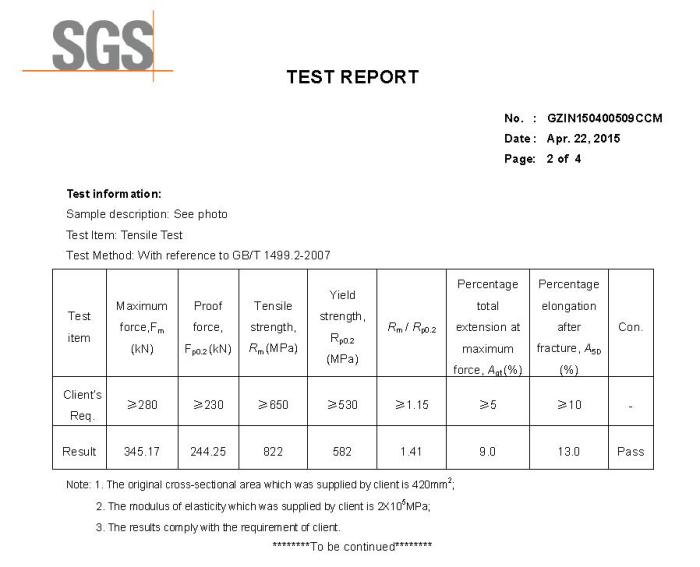

The following is a copy of SGS report which tells the result of tensile test.

The results fully achieve the client’s requirements:

- The test of bars is performed full size.

- The minimum tensile strength is 237 MPa above the minimum yield strength. It is better than the specified 25 000 psi (172 MPa) at least by F432.

- Strength and ductility performance are up to the standards simultaneously.

In fact, ONTON has a range of standard self-drilling anchor rods. These rods are special treated to gain high resistance capacity. That means:

- For a same cross section of steel, the load bearing capability of ONTON rods is up to 40% higher, allowing for a larger nailing grid or a smaller size (diameter) of bar rods. Project cost saving.

- For a same tensile strength, our rods are lighter. Labor cost saving.

In the end of tensile test, if the strain increased even more, eventually the object will neck. During elastic and plastic deformation the entire object’s cross-sectional area decreases slightly, but at the onset of necking the weakest part of the material suddenly becomes noticeably thinner. It takes less force to finish pulling the steel pipe apart.

Furthermore, you may notice the Ductility Agt parameter in the SGS report.

How they measured Agt of self-drilling hollow bar?

First you should understand the the difference between Agt and A.

Ductility means that in design calculation, assumptions for classification and rotation of hinges are accepted. Agt denotes the elongation up to ultimate load without reduction of cross-section. This is not to be confused with total elongation, A, up to rupture, as described in ASTM A370 and stated on mill certificates. Usually elongation, a, has double the value of Agt The ductility of Agt > 5% is required for the finished hollow-bar, not for the steel tube it is manufactured from and which is given on the mill certificate of the steel mill.

(The information is from the Titan website)

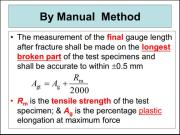

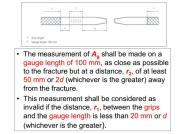

How to measure Agt of the hollow bar?

Assume the tensile strength of this hollow bar, Rm = 800 N/mm2

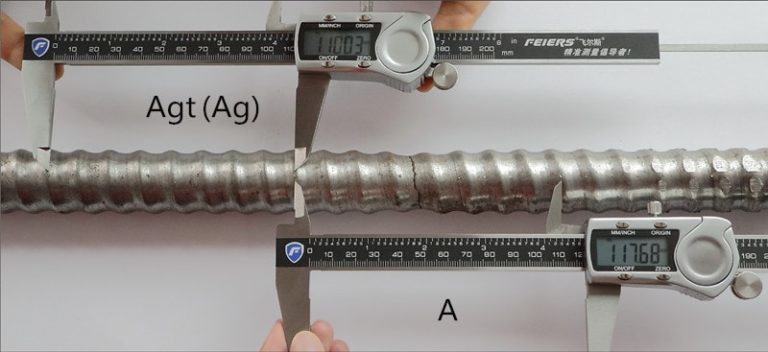

Measurement (as shown) and calculated:

Agt = Ag+ Rm / 2000

Ag = {(110.03mm-100mm) / 100mm}*100 = 10

Rm / 2000 = 800 / 2000 = 0.4

Agt = 10.4

A = {(117.68mm-100mm) / 100mm}*100 = 17.6

Result: The elongation of the hollow bar: Agt = 10.4(%) A = 17.6(%)